In today’s fast-paced industrial world, efficient and precise liquid handling is a key factor in ensuring optimal production processes. Whether you're handling engine oil, motor oil, lubricants, liquid soap, or chemicals, an advanced drum filling machine can streamline your production and improve the overall efficiency of your operations. At GLZON, we provide industry-leading drum filling equipment designed to deliver fast, accurate, and spill-free filling for 200L drums, 220L barrels, and 1000L IBC totes. Our drum filling system is built to meet the needs of businesses across various industries, providing precision, speed, and reliability at every step.

Why Invest in a Drum Filling Machine?

A drum filling machine is essential for industries that require quick and accurate filling of large containers. The right drum filling system can transform your production lines by increasing speed, reducing wastage, and enhancing overall quality. Let’s take a closer look at the benefits of using a drum filling machine in your business.

1. Precision and Accuracy

The most important feature of any drum filling equipment is its ability to ensure that the correct amount of liquid is dispensed into each container. Our automatic drum filling machine uses weight-based precision technology to guarantee that every drum, tote, or barrel is filled accurately, minimizing product wastage and improving consistency. Whether you’re filling engine oils, lubricants, or chemicals, the ability to fill each container with the exact amount of liquid required is essential for maintaining product quality and reducing losses.

2. Spill-Free Operations

Spills during the filling process can lead to costly product losses and hazardous working conditions. Our drum filling system is equipped with anti-drip nozzles, ensuring a clean and spill-free filling process. This not only saves money by preventing wastage but also helps maintain a safer working environment.

The advanced automatic drum filler system guarantees that every fill is precise, reducing the likelihood of spills or contamination. This feature is especially important when dealing with expensive or hazardous materials such as chemicals or oils, where even small leaks can result in significant financial losses.

3. High-Speed Performance

In today’s competitive manufacturing environment, speed is a critical factor. The drum filling machine is designed for high-speed operations, filling multiple containers in a fraction of the time it would take using manual labor. This feature is particularly important for businesses dealing with large volumes of product, where efficiency and quick turnaround are crucial to meeting customer demand.

By incorporating an automatic drum filling system, businesses can significantly increase their filling speed without compromising on accuracy or precision. Our drum filling equipment is capable of filling up to 40-60 containers per hour, depending on the size and type of liquid being filled.

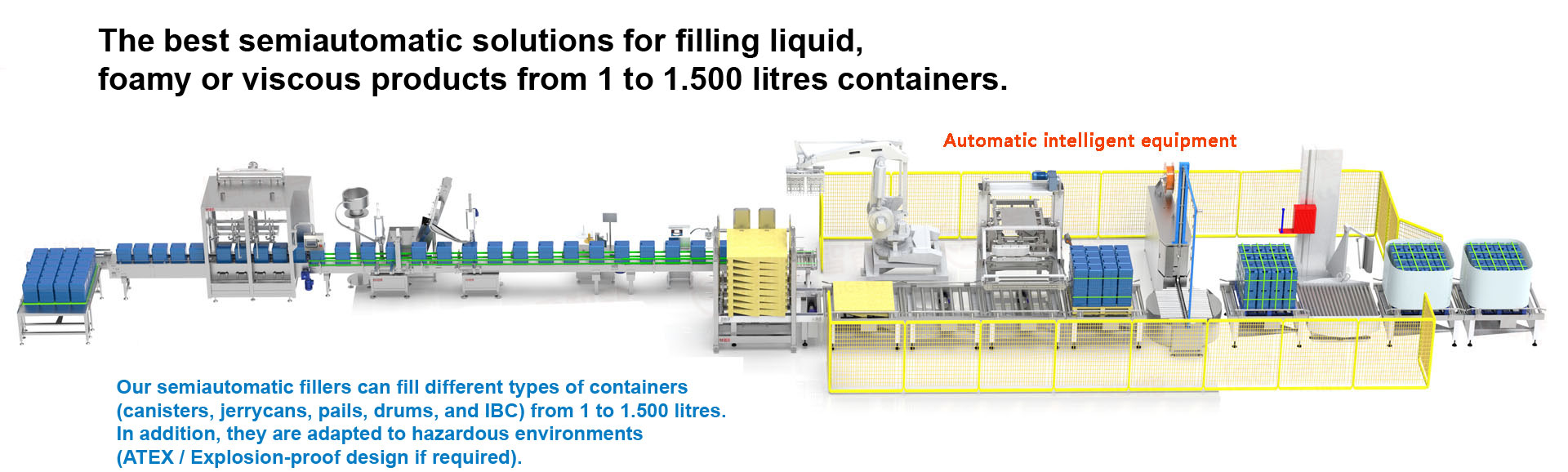

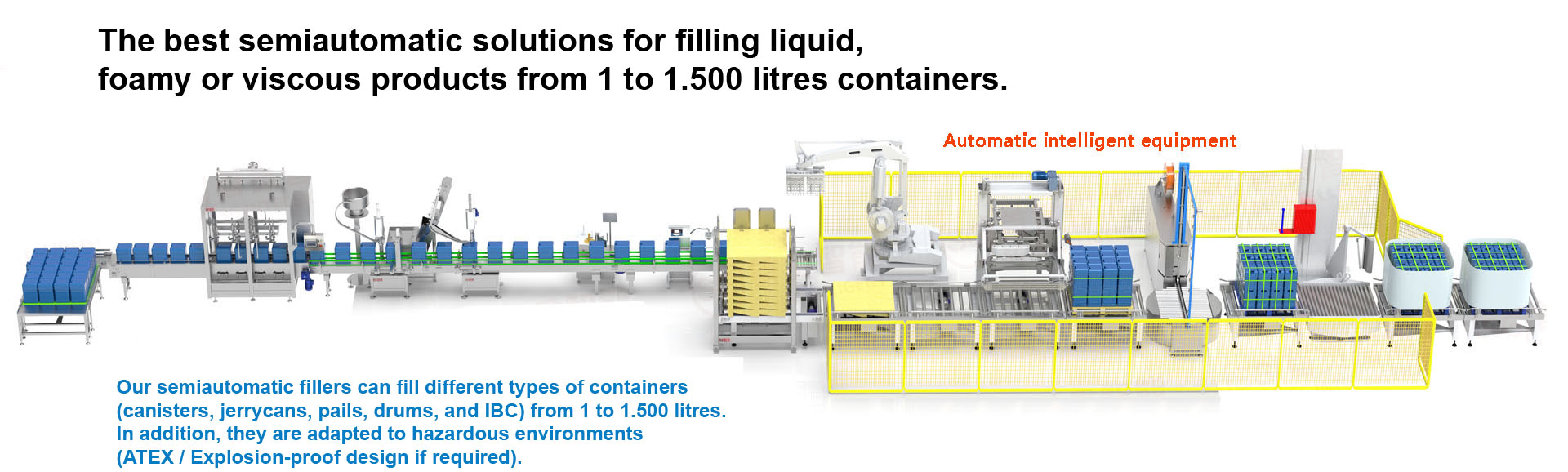

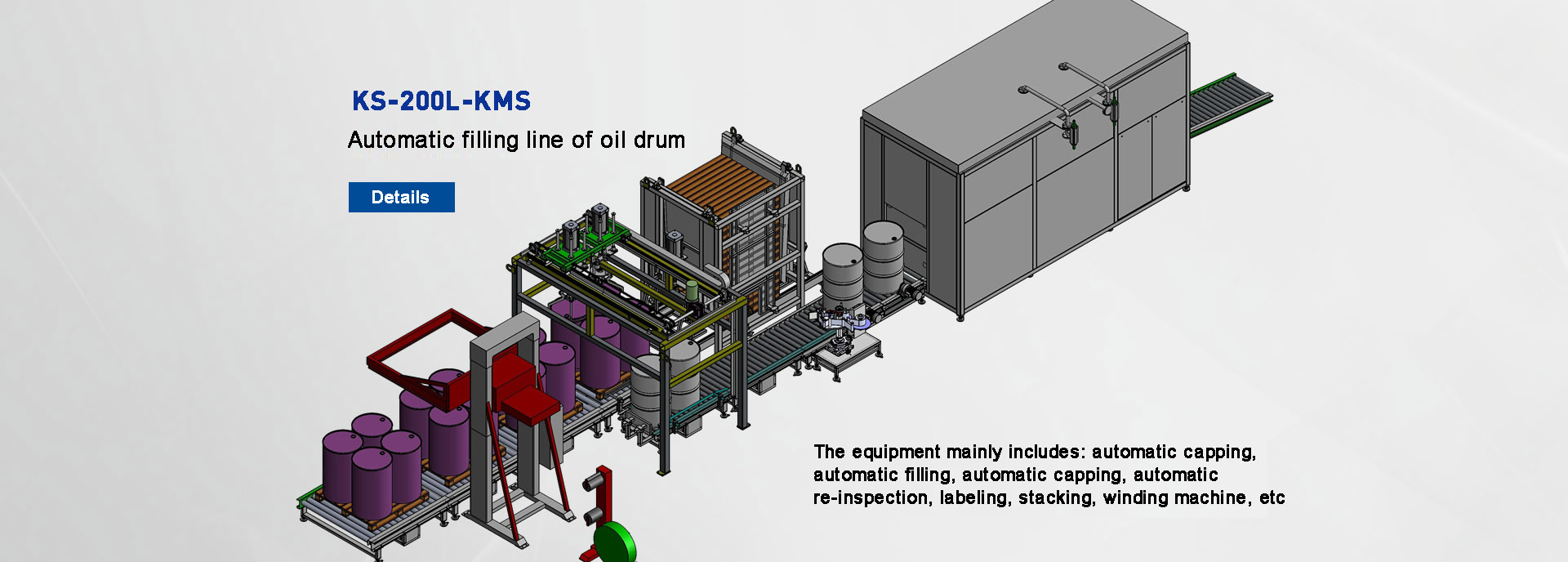

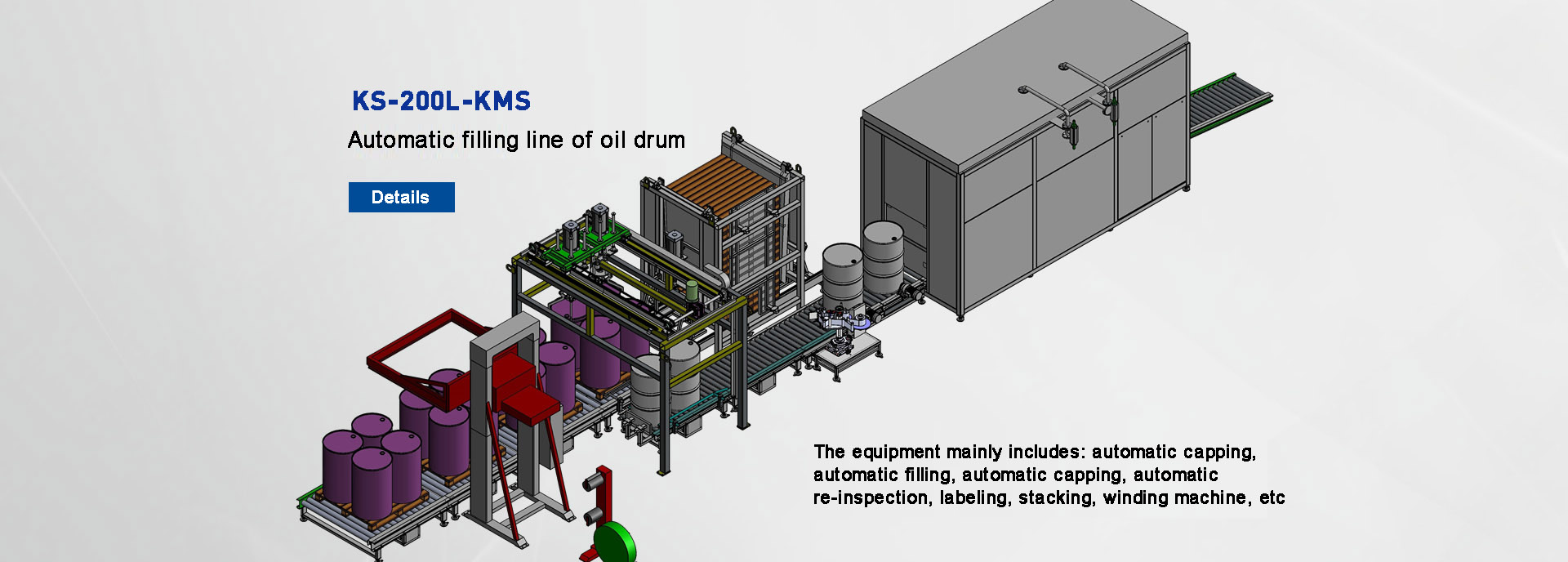

4. Seamless Integration into Your Production Line

One of the key benefits of using a drum filling machine is the ease with which it can be integrated into your existing production line. Whether you are using a semi-automatic or fully automated system, our drum filling equipment is designed to fit smoothly into your current operations, making it easier to scale your business without major disruptions.

The drum filling system can be customized to match your production requirements, whether you are filling lubricants, resins, or motor oils. This flexibility makes it an ideal solution for a wide range of industries, from automotive to chemical manufacturing.

5. Versatility in Application

Another major advantage of our drum filling system is its versatility. Our automatic drum filling equipment can be used for a wide variety of liquids, including engine oils, liquid soap, chemicals, and more. The drum and tote filling machines are built to handle different viscosities, making them suitable for filling both thin liquids (like water) and thicker liquids (like oils and lubricants).

Additionally, the machine can handle 200L drums, 220L barrels, and 1000L IBC totes, ensuring that your business is equipped to manage various container sizes, improving overall efficiency and flexibility.

Order Your Drum Filling Equipment Today!

Key Features of Our Drum Filling Equipment

Our drum filling system is equipped with several key features that enhance its performance and make it the ideal solution for high-volume filling operations:

Weight-Based Precision: Ensures accurate filling and minimal wastage.

Anti-Drip Technology: Prevents spills and keeps your production area clean.

High-Speed Performance: Allows for faster turnaround times, increasing productivity.

Versatile Operation: Handles a wide range of liquids, from oils to chemicals.

Seamless Integration: Can be easily incorporated into existing production lines.

These features combined make our drum filling machine an indispensable asset for any business that needs efficient, reliable, and high-speed liquid filling.

Types of Liquids That Can Be Filled Using Our Drum Filling System

Our drum filling system is ideal for a wide range of industries, including those involved in the production of oils, chemicals, liquid soaps, and lubricants. Here are some of the liquids that our drum filling equipment can handle:

Engine Oil: Our automatic drum filling machine ensures precise and spill-free filling of engine oil, improving the overall efficiency of your automotive production line.

Lubricants and Motor Oil: Designed to handle high-viscosity liquids, our system fills lubricants and motor oils quickly and efficiently, ensuring that every drum is filled with the correct amount of liquid.

Chemical Solutions: Whether you're filling industrial chemicals or detergents, our drum filling machine provides precise filling, maintaining the integrity of your products.

Liquid Soap and Personal Care Products: Ideal for liquid soaps, shampoos, and other personal care items, our drum filling system ensures hygienic and accurate filling, meeting the strict standards of the cosmetic industry.

Order Your Drum Filling Equipment Today!

Ready to enhance your production with a high-precision drum filling system? At GLZON, we offer automatic drum filling machines that ensure efficient, accurate, and spill-free filling for 200L drums, 220L barrels, and 1000L IBC totes.

Order Now

APPLICABLE BARREL TYPE

COMPANY PROFILE

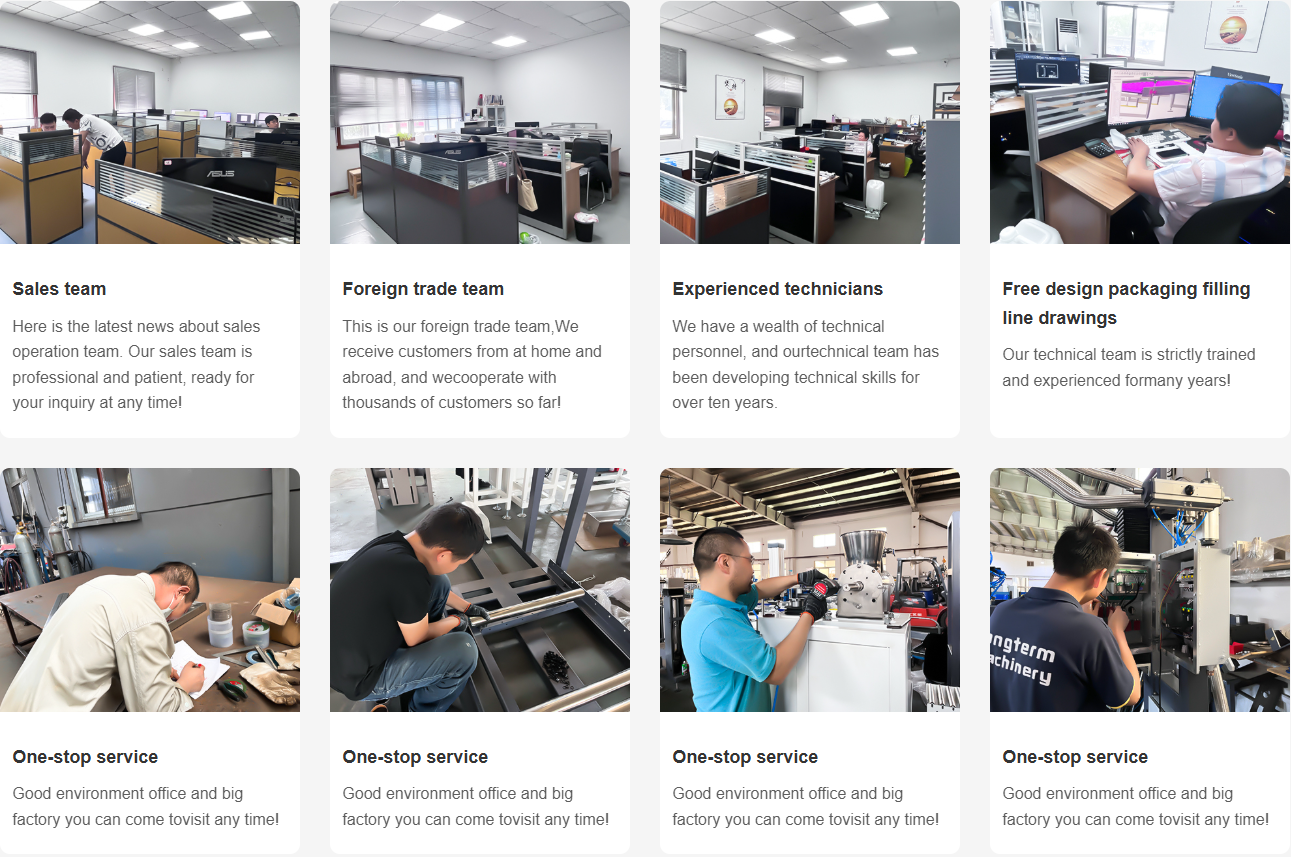

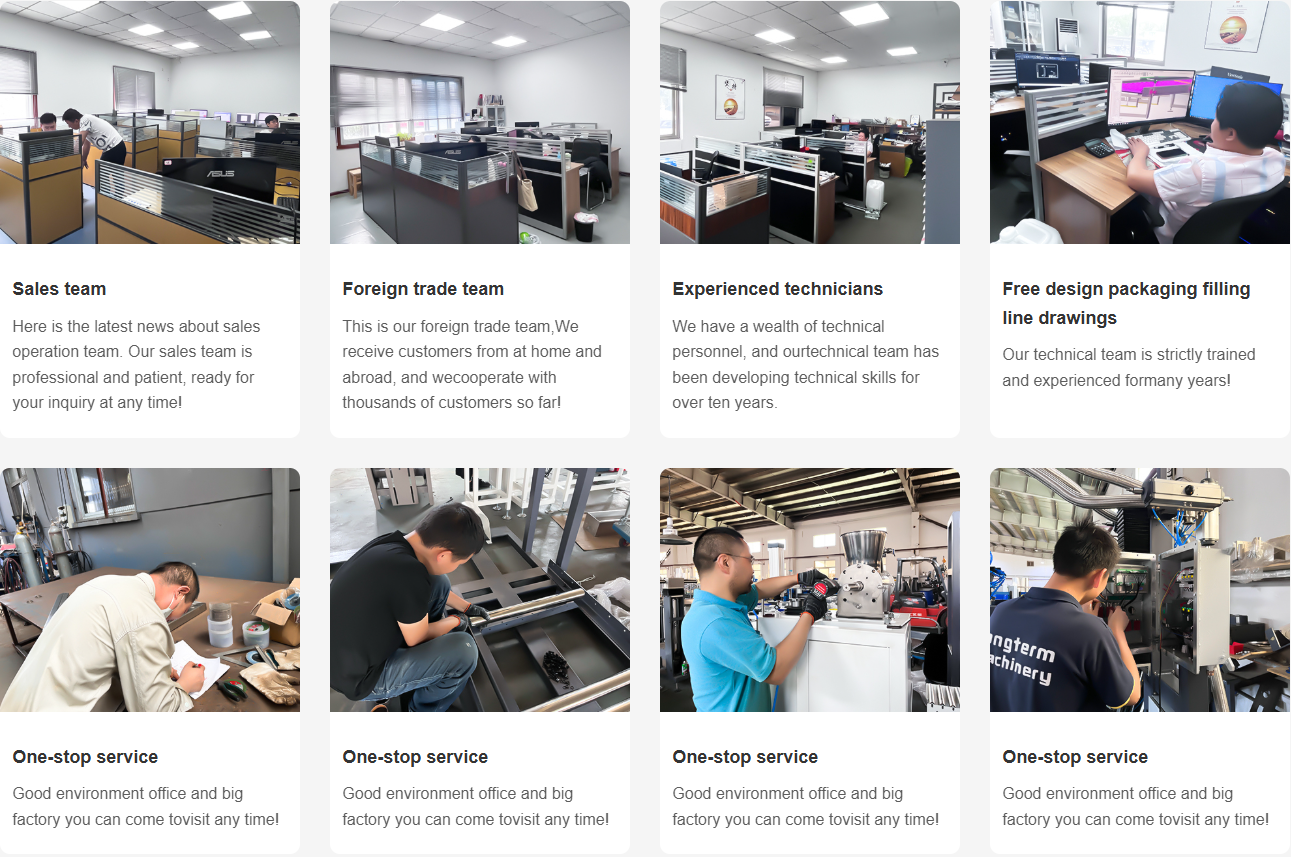

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

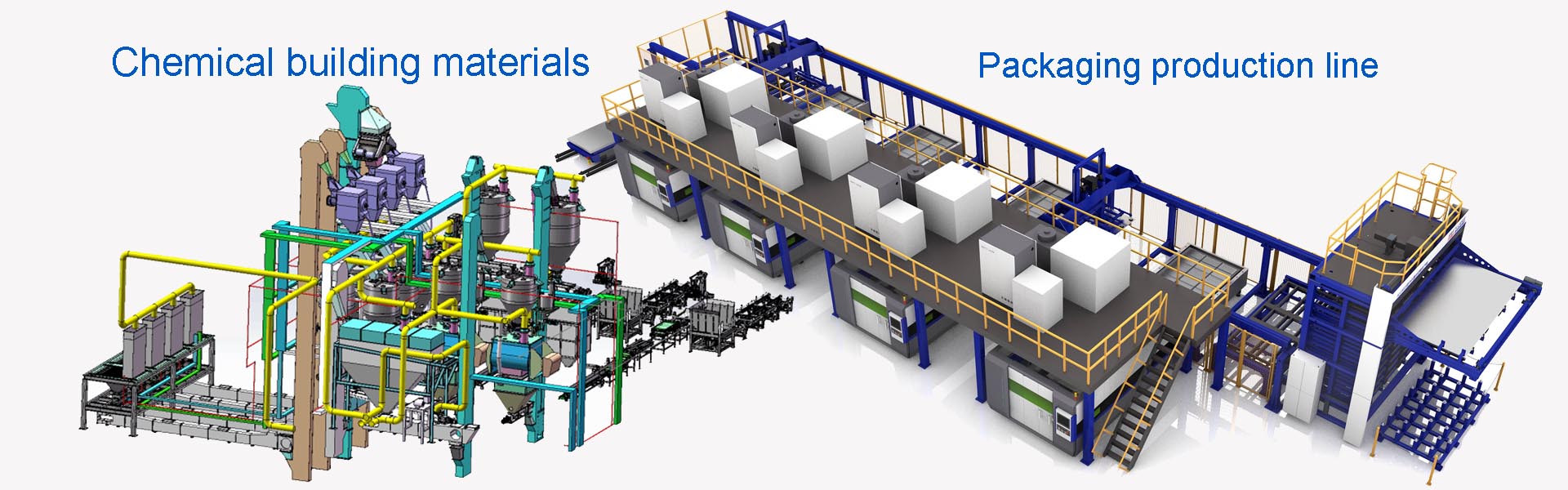

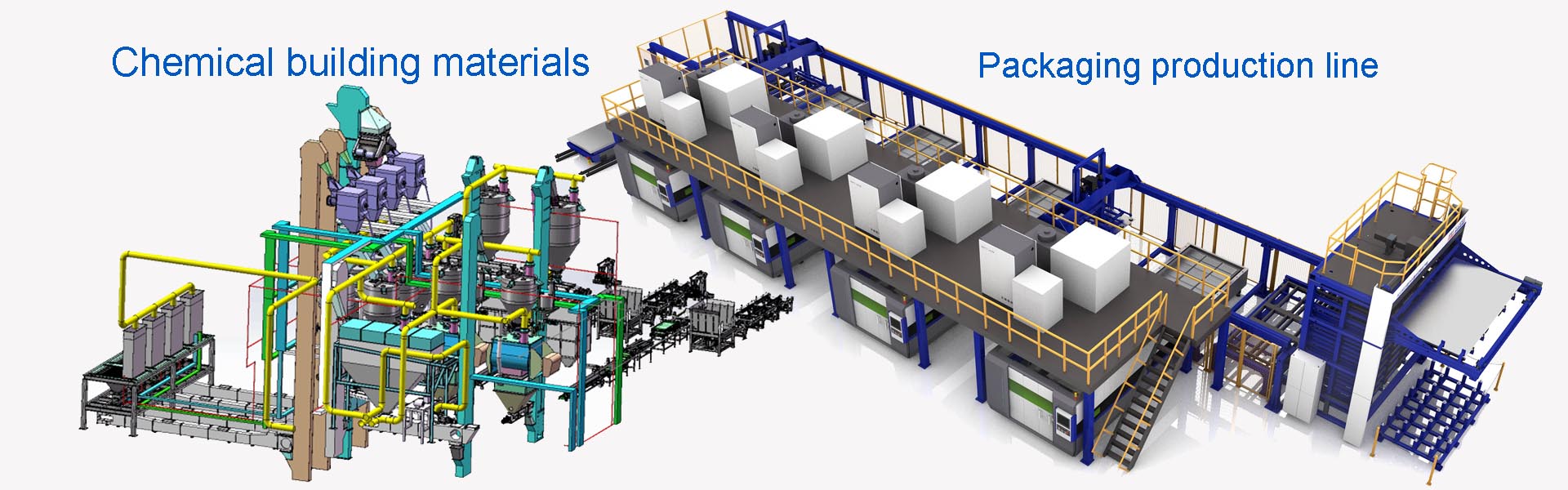

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Company Certificate

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

This is a partial

service for us

in China.

Over 30 years of experience, every time we produce in

Shanghai, our friends can visit our factory at any time.

Brand components

We will ensure that our company's equipment has safety, stability, high efficiency and intelli-gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternational product brand production and business.

Our service

Complete solution provided

Telephone exchange joint business design plan, you can also visit our company ; we have a good environmental office vehicle,you can visit from time to time.

Duty after death

Our music team has a strong heart, and the customer's suspicions are also the purpose 24 hours of phone cell service and listing to the conversation at any time.

Technology group

We have a wealth of technical personnel and our technical team has been developing technical skills for over ten years.

Successful collaboration

Our factory in Shanghai. China provides free training for our technical staff.Better guarantee good product safety , our company provides safety, convenience, high efficlency packaging servic.

packge and delivery

Multiple Transportation way :Express(Fedex/DHL/TNT/EMS/UPS etc),air and shipping for your choose

Our in-house designers and engineers have produced countless great designs for customers from different industries

1

Can we get your free samples?

Samples can be offered for free. But courier cost for the samples should be at buyer's account.

2

Can you print our LOGO in flatware set?

Yes.we can print the logo on the flatware set as your requirements.Embossed, laser,stamped and engraved are available.

3

How long is the delivery time of sample?

Samples from stock can be sent within 1-3 days. New produced samples will be sent within 5-15 days.

4

Is there any MOQ for what I purchase?

Yes, we have MOQ for mass production. Different item with different package has different MOQ. Please contact us for more details.

5

Do you accept OEM or ODM services?

OEM and ODM are accepted!

6

What is 18-10 Stainless Steel Flatware?

18-10 refers to the composition of stainless steel. It contains 18% chromium and 10% nickel for excellent strength and corrosion resistance.

CONTACT US

Skype: fayfaywang1027

QQ: 429682794

Whatsapp: 008618016442021

E-mail: glzoncn@163.com

https://glzon.en.alibaba.com/

cel: +0086 18016442021