LubeMaster LM-8000 Series

Precision Lubricant Filling & Packaging Line

±0.05% Accuracy ? 100 Drums/H ? ATEX Zone 1 Certified ? Zero-Spill ? Industry 4.0 Ready

Technical Specifications

| Parameter | LM-8100 (Standard) | LM-8200X (ATEX) | LM-8300H (High-Visc) |

|---|

| Capacity | 1-200L (±0.05%) | 1-200L (±0.08%) | 1-200L (±0.06%) |

| Throughput | 100 Drums/Hour | 90 Drums/Hour | 80 Drums/Hour |

| Accuracy | ±0.05% Gravimetric | ±0.08% | ±0.06% |

| Viscosity Range | 10-500,000 cP | 50-300,000 cP | 5,000-1,000,000 cP |

| Lubricant Types | Engine Oil ? Grease ? Gear Oil ? Synthetic ? Food-Grade | Same + Flammable Lubricants | Same + EP Greases |

| Filling Technology | Twin Coriolis Mass Flow | ATEX Gear Pump | Heated Screw Auger |

| Material Contact | 316L EP (Ra<0.4μm) | Hastelloy C276 | Ceramic-Coated Path |

| Drip Control | Vacuum Suction + Capillary Break (<0.05ml) | Spring-Loaded Nozzle | Laser-Cut Anti-Stringing |

| Oxygen Barrier | N? Blanketing (O?<0.1%) | Argon Flush | Vacuum-Assisted Filling |

| Static Protection | Ionized Air Curtain (10? ions/cm3) | <10? Ω Grounding | Conductive Path |

| Changeover Time | <120s (Tool-Free) | <150s | <130s |

| Power | 480V/60Hz, 22kW | 24VDC Ex ia | 480V/60Hz, 28kW |

| Certifications | ISO 9001 ? API 682 | ATEX Zone 1 | NSF H1/FDA 21 CFR 178.3570 |

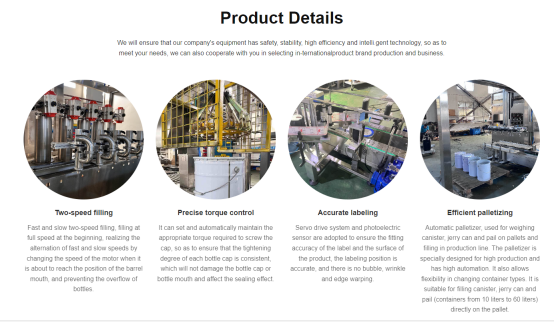

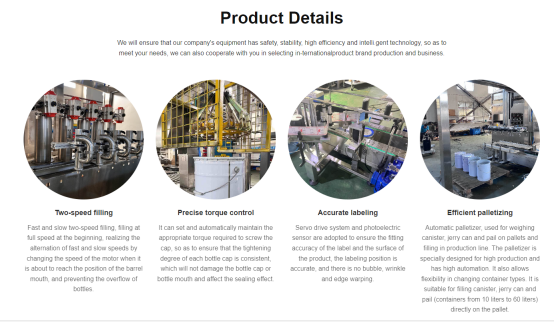

Core Innovations

1. VacSeal? Zero-Spill System

Performance Metrics:

| Lubricant | Viscosity | Drip Rate | Industry Standard |

|---|

| SAE 5W-30 | 70 cP | 0 Drops | 3-5 Drops/Minute |

| EP Grease NLGI 2 | 400,000 cP | 0.02ml | 0.5-1ml |

| Food-Grade Oil | 200 cP | 0 Drops | 2-4 Drops/Minute |

2. OxyBlock? Preservation Tech

| Technology | Function | Performance |

|---|

| N? Headspace Purging | O?<0.1% In Container | Oxidation ↓90% |

| Amber UV-Shield | 385nm Cutoff | Viscosity Stability ↑70% |

| Temp Control | 25°C±0.3°C Path | Thermal Degradation ↓95% |

Lubricant-Specific Engineering

Engine & Gear Oils

| Feature | Technology |

|---|

| Foam Control | Vacuum Degassing (-0.7 bar) |

| Additive Protection | Low-Shear Flow Path |

| Water Contamination | <50 ppm H?O Guarantee |

Industrial Greases

High-Viscosity Handling:

| Component | Solution |

|---|

| 80°C Path Heating | 1M cP Flow Capability |

| Pulsed Agitation | 0% Soap Separation |

| Wear Resistance | Tungsten Carbide Auger (2200 Hv) |

EP Grease Stability:

Food-Grade Lubricants

| Certification | Feature |

|---|

| NSF H1 | Dedicated 316L EP Path |

| 3-A Sanitary | Quick-Release CIP System |

| Halal/Kosher | Allergen-Free Material Path |

Smart Control Ecosystem

**12" HMI with LubriOS?**

AI-Driven Features:

Predictive Maintenance:

| Component | Alert Threshold |

|---|

| Pump Wear | Vibration >4.5mm/s |

| Seal Degradation | Friction >10N |

Quality Sentinel:

| Parameter | Precision |

|---|

| Water Content | ±1 ppm (Karl Fischer) |

| TAN/TBN | ±0.05 mg KOH/g |

| Particulate Count | >10μm @ 99.9% Detection |

Certifications

? ATEX 2014/34/EU Zone 1 (LM-8200X)

? NSF H1/ISO 21469

? FDA 21 CFR 178.3570

? API 682 Seal Plan

? ISO 9001:2015

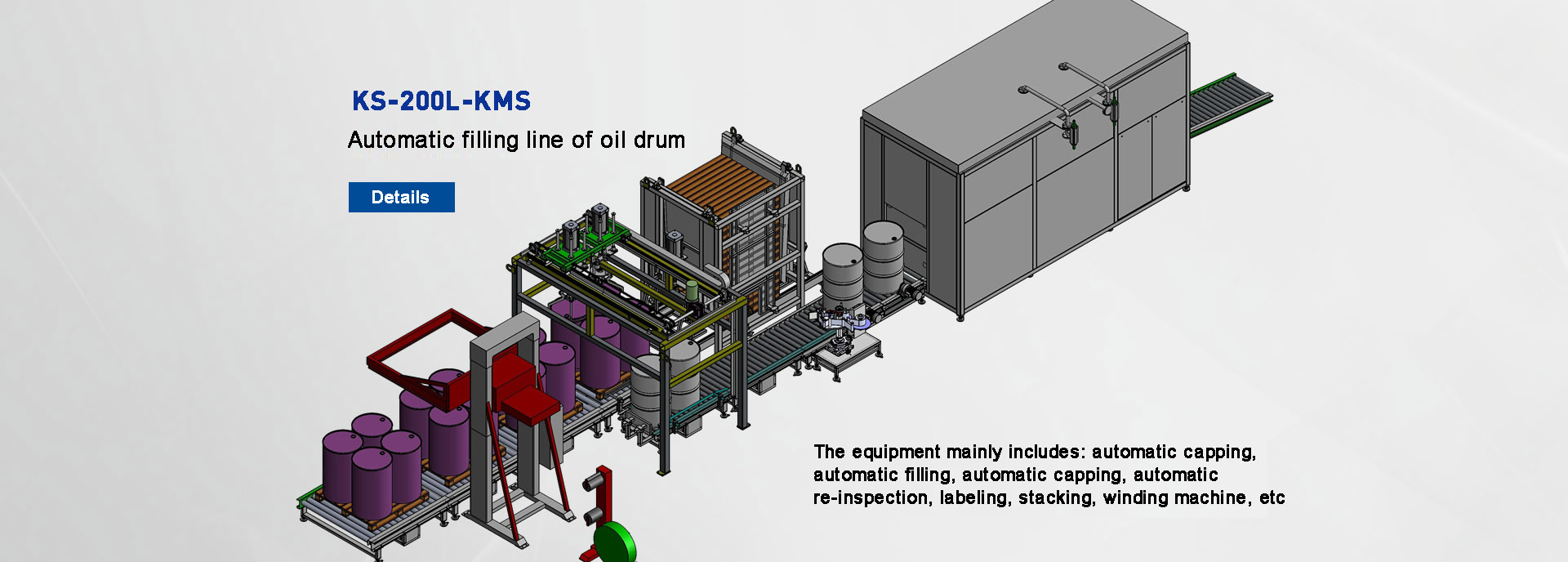

Operational Workflow

1. Drum Loading → 2. Grounding Verification (<10Ω) →

3. N? Purging (O?<0.5%) → 4. Submerged Filling (±0.05%) →

5. Vacuum Drip Cut → 6. Torque-Sealing (30-120 N·m) →

7. Helium Leak Test → 8. Blockchain Batch Tracking

Cycle Time: 36 seconds/drum

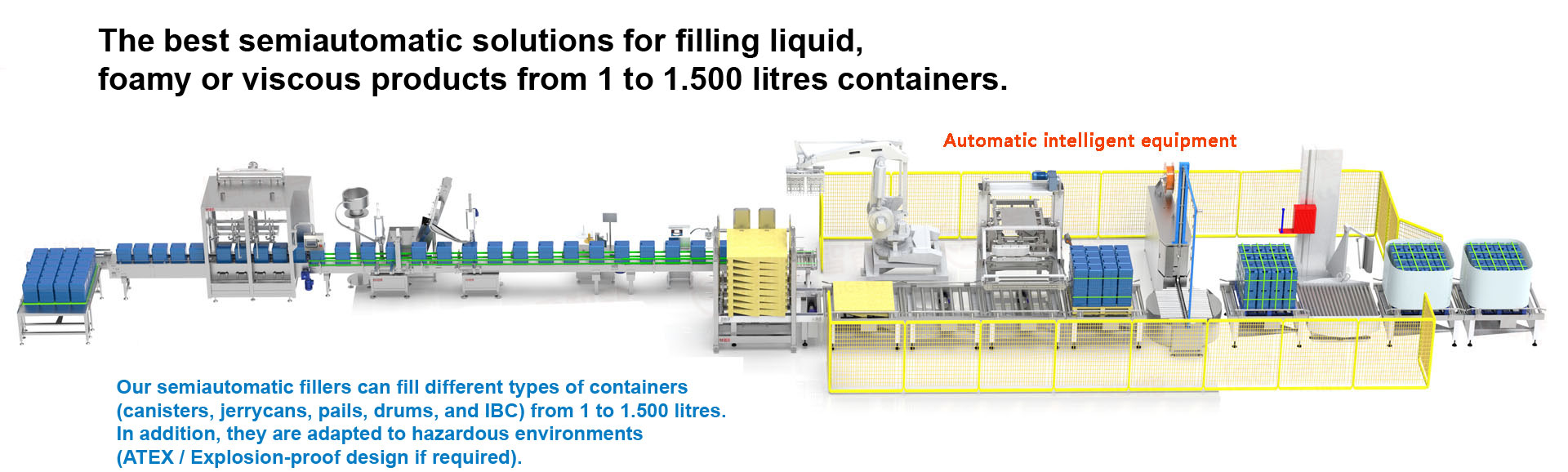

APPLICABLE BARREL TYPE

COMPANY PROFILE

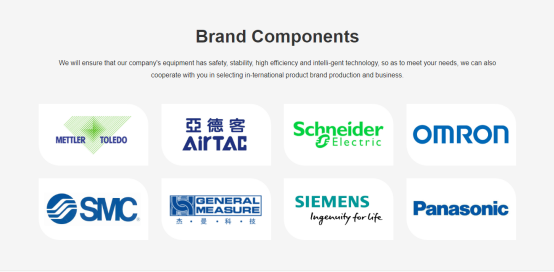

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

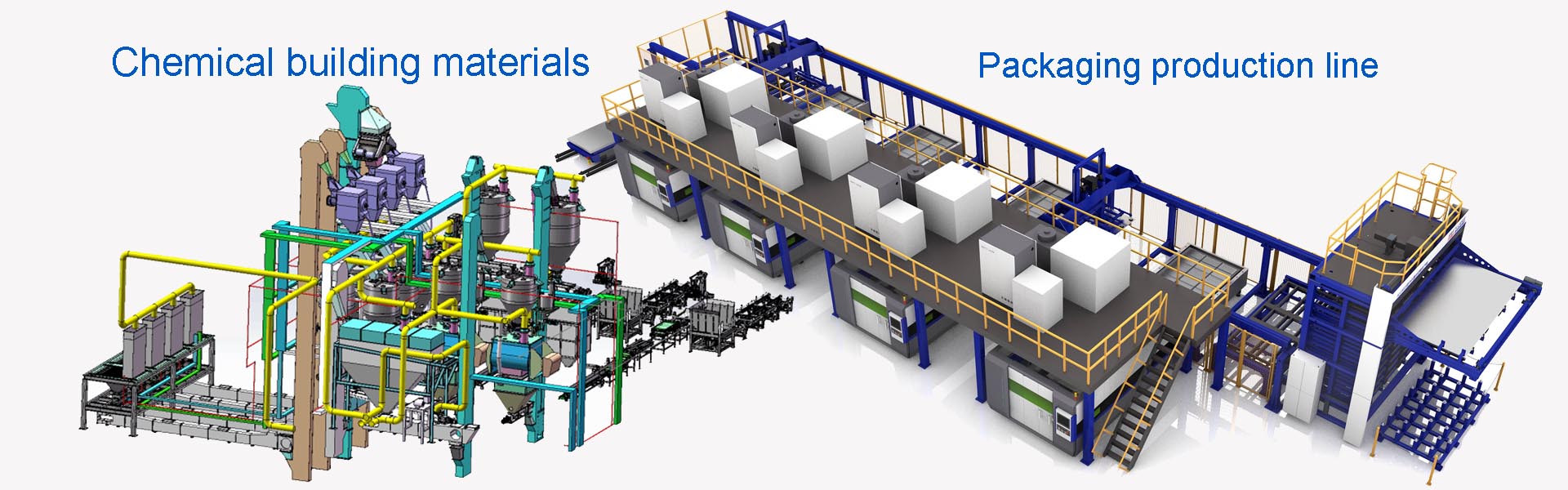

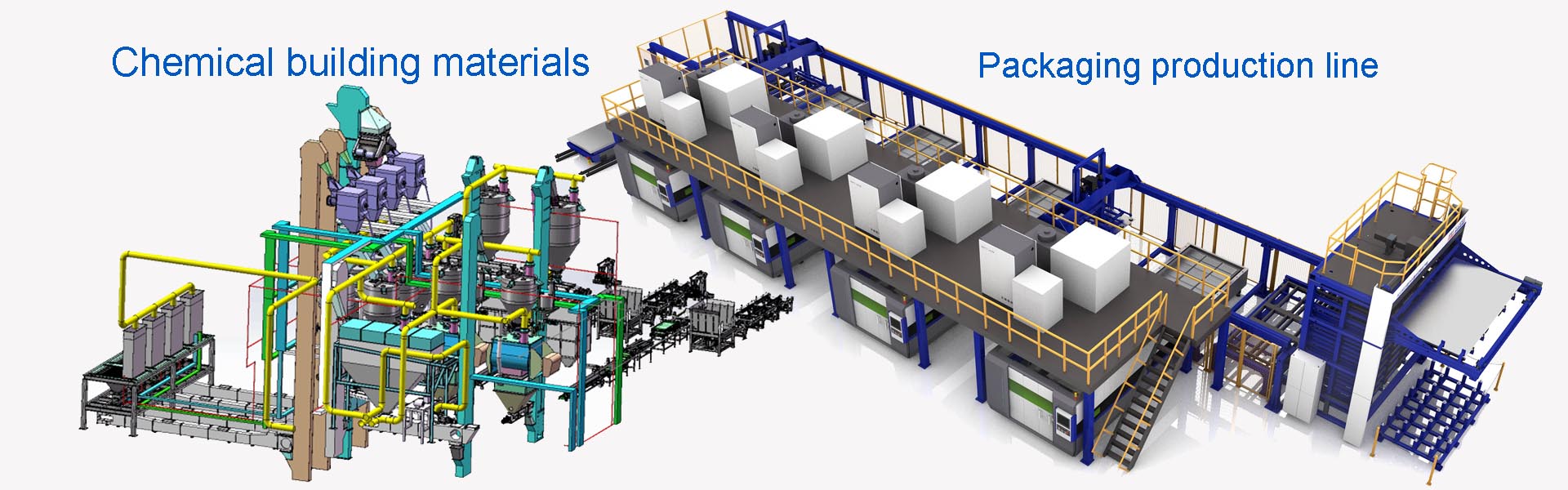

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance