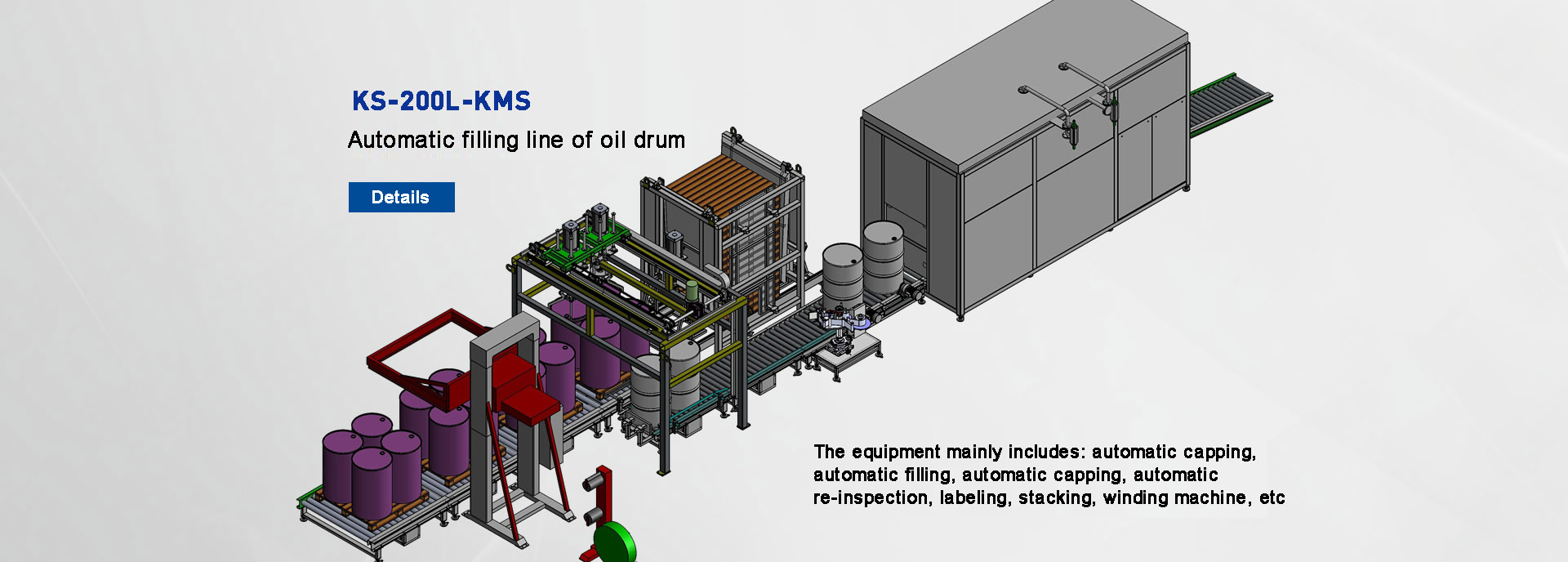

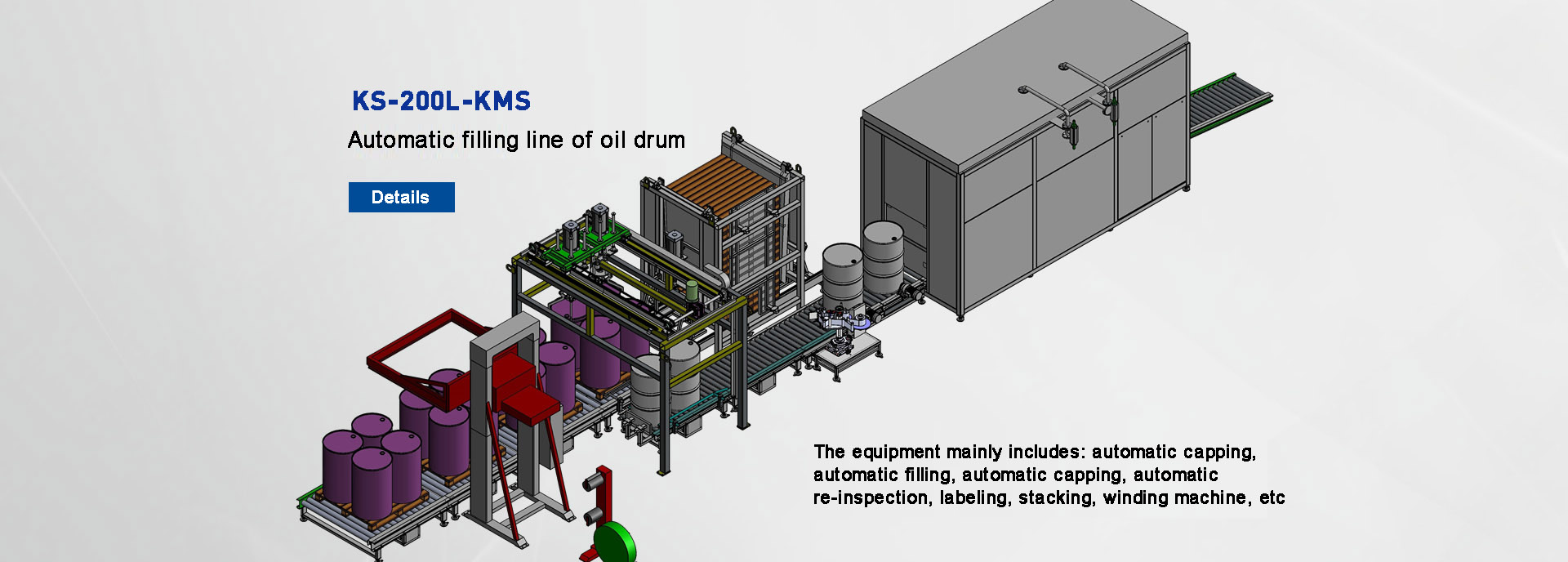

Industrial Paint Filling Machines for Wall Paint - Latex - Coatings

The Complete Guide to Paint Filling Machines for Latex, Wall Paint, and Industrial Coatings

Introduction

In the modern paint manufacturing industry, precision, cleanliness, and automation are crucial to success. Whether you're packaging wall paint, latex, oil-based paint, or epoxy coatings, the right paint filling machine streamlines operations, reduces product loss, and ensures consistency in every container.

This guide covers everything you need to know about industrial paint filling machines — including types, benefits, applications, and how to choose the right system for your production line.

What Is a Paint Filling Machine?

A paint filling machine is specialized equipment designed to fill liquid or semi-liquid paint products into containers such as plastic buckets, metal pails, or tin cans. These machines can be fully automatic or semi-automatic, depending on production volume and budget.

They are widely used to fill:

Wall paint / latex paint

Oil-based paints

Industrial coatings

Varnish and wood stain

Epoxy and UV coatings

Protective paints and asphalt emulsions

Common Container Types

Paint products are typically packaged in:

1-gallon, 3.5-gallon, and 5-gallon pails

Metal paint cans (quart to gallon sizes)

Plastic buckets

Small drums (15–30 gallons)

A good filling system should support various sizes without manual changeover.

Types of Paint Filling Machines

1. Automatic Paint Filling Machine

This high-speed system is designed for mass production and includes:

Net weight or volumetric filling

Automatic lid placing and crimping

Anti-drip nozzles

Conveyor belt integration

Explosion-proof options for flammable solvents

Best for:

Filling latex paint, oil-based paint, water-based coatings, and epoxy into metal or plastic buckets from 1–5 gallons.

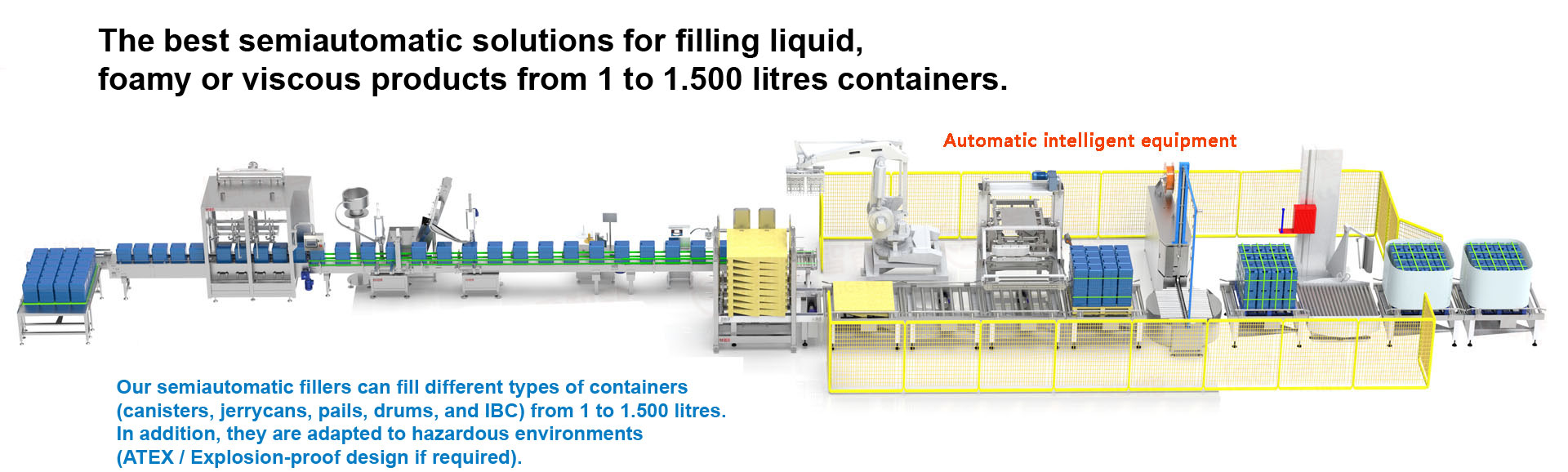

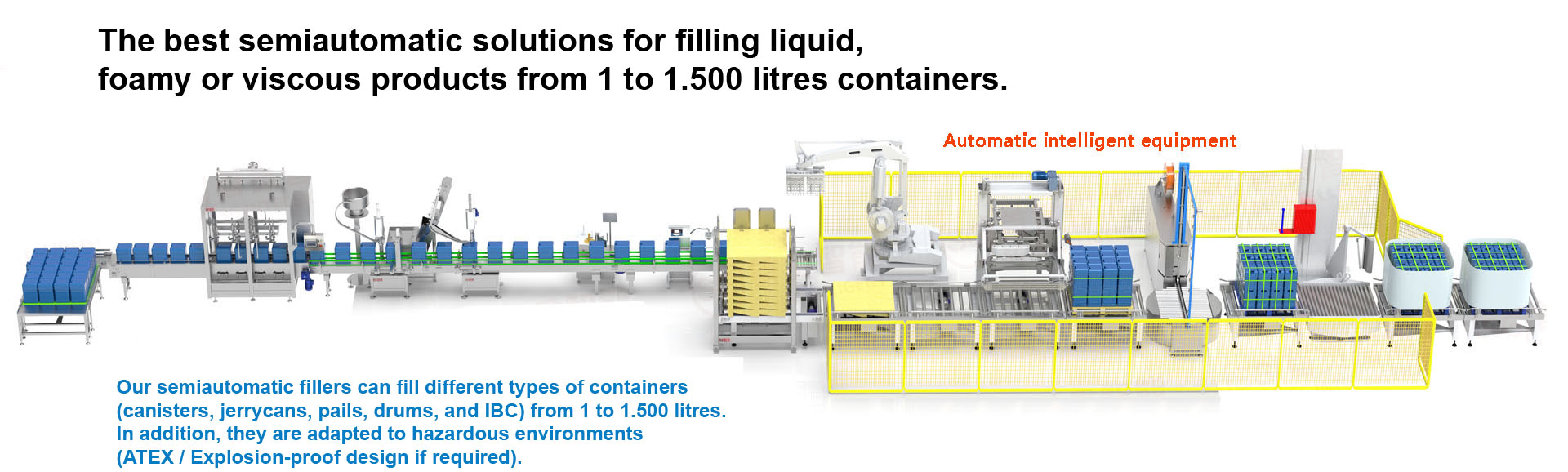

2. Semi-Automatic Paint Filling Machine

Ideal for medium-capacity operations. The operator manually places the container; the machine handles the fill by weight or volume.

Advantages:

Flexible container handling

Lower initial investment

Simple maintenance

Best for:

Manufacturers with a wide variety of paint types and packaging sizes, or those filling industrial coatings, asphalt emulsions, and small-batch custom colors.

Key Features to Look For

Net Weight Filling: Ensures accurate and consistent paint weight in every container.

Anti-Drip Nozzles: Prevents spills and keeps pails clean.

Lid Crimping Systems: Automatically seals the filled paint cans or pails.

PLC Touchscreen Control: Easy recipe setup for different paint types and viscosities.

Explosion-Proof Design: Essential for flammable or solvent-based paints.

Types of Paint Handled

Modern machines are compatible with various paint and coating types, including

Wall Paint / Latex Paint

Water-based decorative paints for interior and exterior surfaces.

Oil-Based Paint

Solvent-based products requiring explosion-proof components.

Industrial Coatings

High-viscosity materials for equipment, floors, or pipelines.

Epoxy Coatings & Varnish

Used for wood, metal, and protective finishes.

UV Coatings & Inks

Requires precision dosing and anti-curing precautions.

Asphalt Emulsion & Protective Coatings

High-volume filling for road surfacing or sealing products.

Benefits of Using a Paint Filling Machine

? Speed Up Production

Automatic systems can fill hundreds of buckets per hour.

? Improve Fill Accuracy

No underfilled or overfilled containers.

? Reduce Spillage and Waste

Clean filling = lower material loss and better branding.

? Labor Cost Reduction

Less manual work and fewer operators required.

? Better Quality Control

Consistent fill levels and sealing.

How to Choose the Right System

When choosing your machine, consider:

Viscosity of Your Paint:

Thicker paints like epoxy need pressurized or piston-style fillers.Container Types:

Do you fill pails, metal cans, plastic buckets, or a combination?Daily Output Target:

Higher volumes justify an automatic system.Factory Space:

Inline vs. rotary systems vary in footprint.Budget & Future Scalability:

Start semi-automatic and upgrade as your output grows.

Why Net Weight Systems Are Preferred

In paint filling, net weight filling machines are most accurate. They:

Ensure compliance with labeling regulations

Minimize raw material loss

Reduce customer complaints from underfilled containers

Net weight systems also make switching between products easier — simply adjust the fill weight from the touchscreen.

Add-On Functions

Modern paint filling equipment can include:

Lid placing and pressing

Labeling and date coding

Cleaning (CIP) modules

Multiple filling heads for faster throughput

Viscosity compensation for temperature-sensitive paints

Conclusion

If you’re filling wall paint, latex, or coatings into cans or pails, a properly selected paint filling machine will improve your productivity, consistency, and product presentation.

Whether you're scaling up a factory or automating a small workshop, there’s a paint filling system designed for your needs.