How to choose a paint filling machine

Choosing a paint filling machine requires careful consideration of the specific characteristics of paint, your production needs, and the desired level of automation. Here’s a step-by-step guide to help you select the right paint filling machine:

1. Understand Paint Properties

Viscosity: Paints can range from thin (low viscosity) to thick (high viscosity). Ensure the machine is compatible with the viscosity of your paint.

Type of Paint: Consider whether you are filling water-based, solvent-based, oil-based, or specialty paints.

Abrasive or Corrosive Properties: Some paints contain abrasive particles or corrosive chemicals, so the machine materials must be resistant (e.g., stainless steel).

2. Determine Filling Volume and Speed

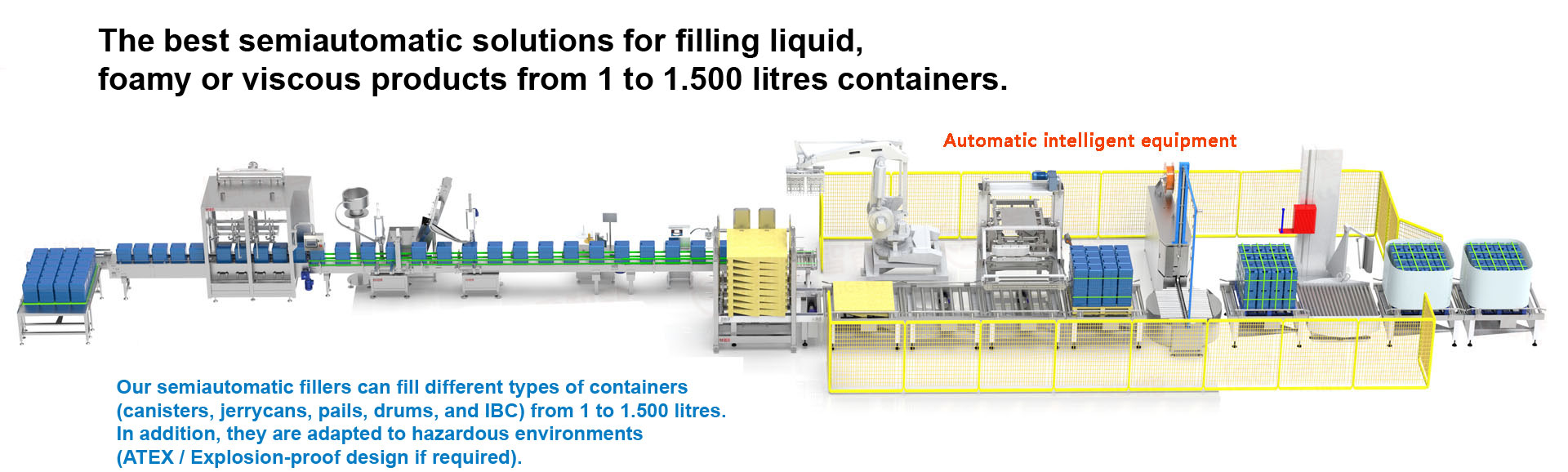

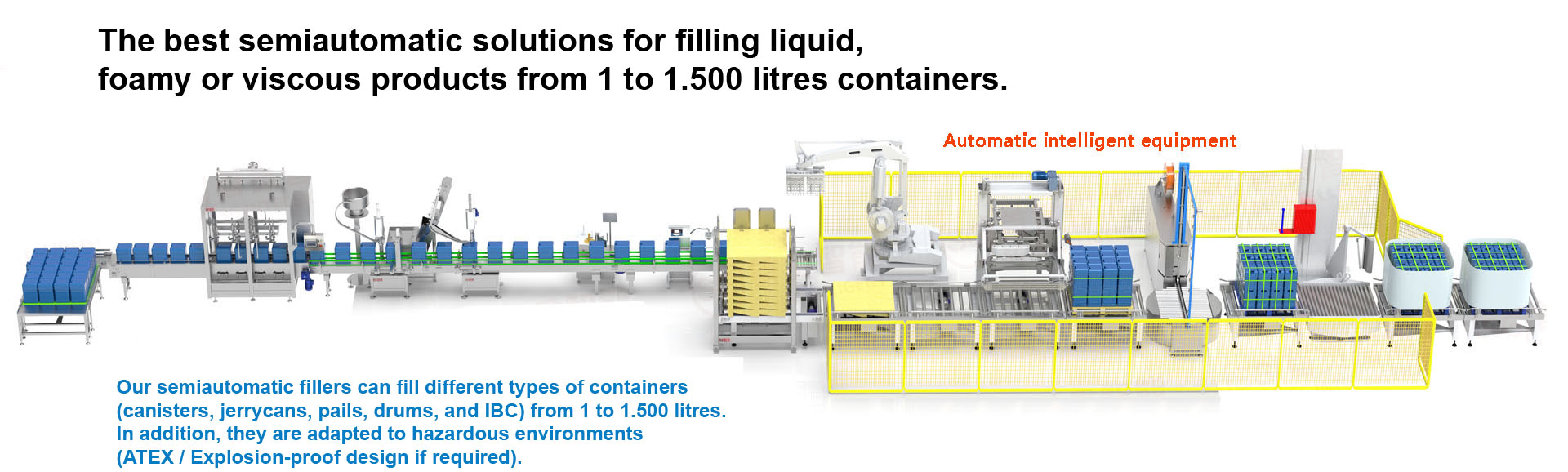

Container Size: Identify the sizes of containers you will be filling (e.g., cans, pails, drums, or IBCs).

Production Volume: Calculate the required output (e.g., containers per hour) to match your production goals.

Filling Accuracy: For high-value paints, precision is critical to avoid overfilling or underfilling.

3. Choose the Right Filling Technology

Piston Filling: Ideal for thick, high-viscosity paints like primers or textured coatings.

Gear Pump Filling: Suitable for medium-viscosity paints.

Peristaltic Pump Filling: Best for paints with abrasive particles, as it minimizes wear and tear.

Gravity Filling: Works for low-viscosity paints.

Net Weight Filling: Suitable for large containers like drums or IBCs, where the paint is weighed during filling.

4. Machine Construction and Materials

Stainless Steel: Preferred for its durability, corrosion resistance, and ease of cleaning.

Seals and Gaskets: Ensure they are compatible with the type of paint being filled to avoid chemical reactions or degradation.

5. Automation Level

Manual: Low-cost option for small-scale or custom production.

Semi-Automatic: Requires some operator intervention but improves efficiency.

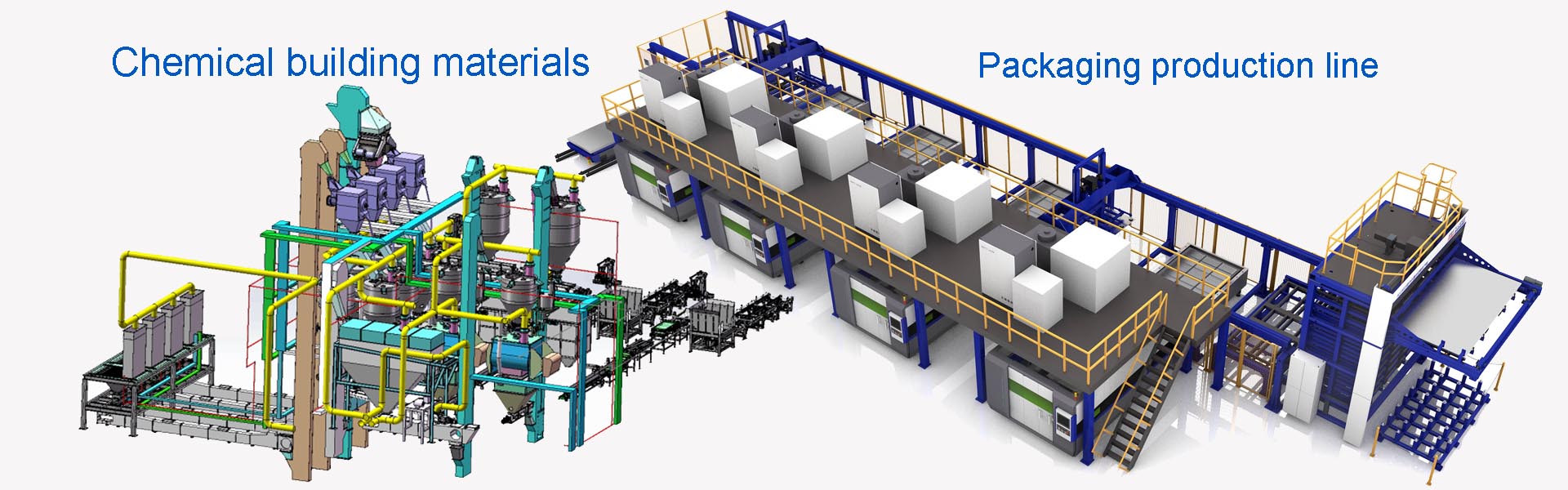

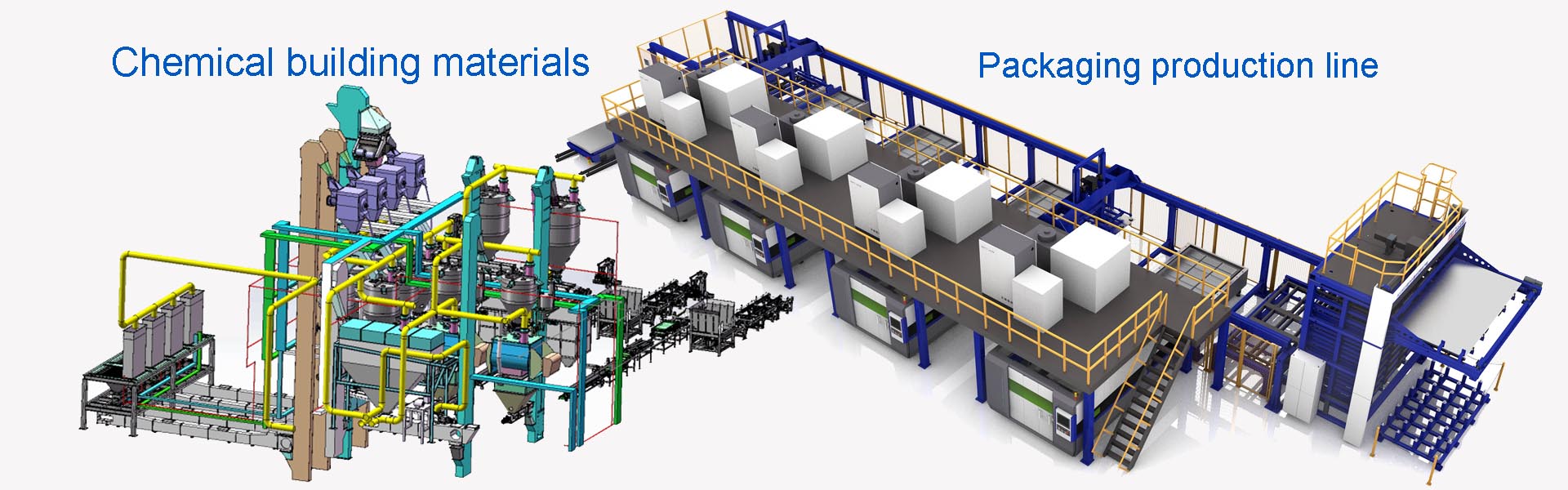

Fully Automatic: High-speed, high-efficiency machines for large-scale production.

6. Container Compatibility

Ensure the machine can handle the types of containers you use (e.g., cans, pails, drums, or IBCs).

Consider how containers will be loaded, filled, and unloaded (e.g., conveyor systems or manual placement).

7. Cleaning and Maintenance

CIP (Clean-in-Place) Systems: Useful for frequent product changes or high hygiene requirements.

Ease of Disassembly: Machines should be easy to clean and maintain to minimize downtime.

8. Safety and Environmental Considerations

Explosion-Proof Equipment: Required for solvent-based paints or paints with flammable components.

Ventilation and Fume Extraction: Ensure the machine can be integrated into a safe working environment.

9. Regulatory Compliance

Ensure the machine meets industry standards and certifications (e.g., CE, ATEX for explosive environments, or FDA for specific applications).

10. Budget and ROI

Compare the initial cost with long-term benefits like increased efficiency, reduced waste, and lower labor costs.

Consider the total cost of ownership, including maintenance and operational costs.

11. Supplier Reputation and Support

Choose a reputable manufacturer with experience in paint filling equipment.

Ensure they offer good after-sales support, training, and spare parts availability.

12. Testing and Trials

Request a demo or trial to test the machine with your paint and containers.

Verify filling accuracy, speed, and ease of operation.

13. Future Scalability

Consider whether the machine can be upgraded or adapted for future needs, such as handling different container sizes or paint types.

Key Features to Look For:

Anti-Drip Nozzles: Prevent spills and waste.

Adjustable Filling Heads: Allow flexibility for different container sizes.

Programmable Controls: Enable easy adjustment of filling volumes and speeds.

Durability: Ensure the machine can withstand the demands of continuous operation.

By evaluating these factors, you can select a paint filling machine that meets your production requirements, ensures consistent quality, and maximizes efficiency. If you need further assistance or real-time translation of related documents, consider using tools that support image-to-text conversion and multilingual translation.