Automatic Double-head Liquid Pail Filling Machine for Engine Oil With a Crown Lid 2

Automatic Double-Head Liquid Pail Filling Machine for Engine Oil with Crown Lid

Overview:

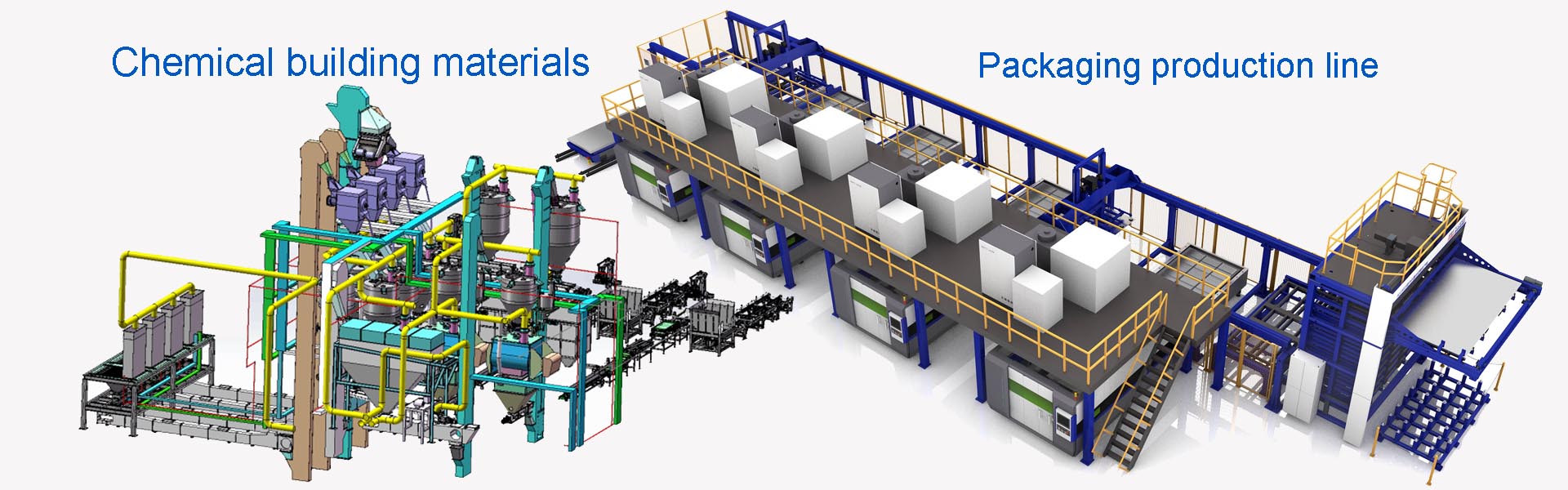

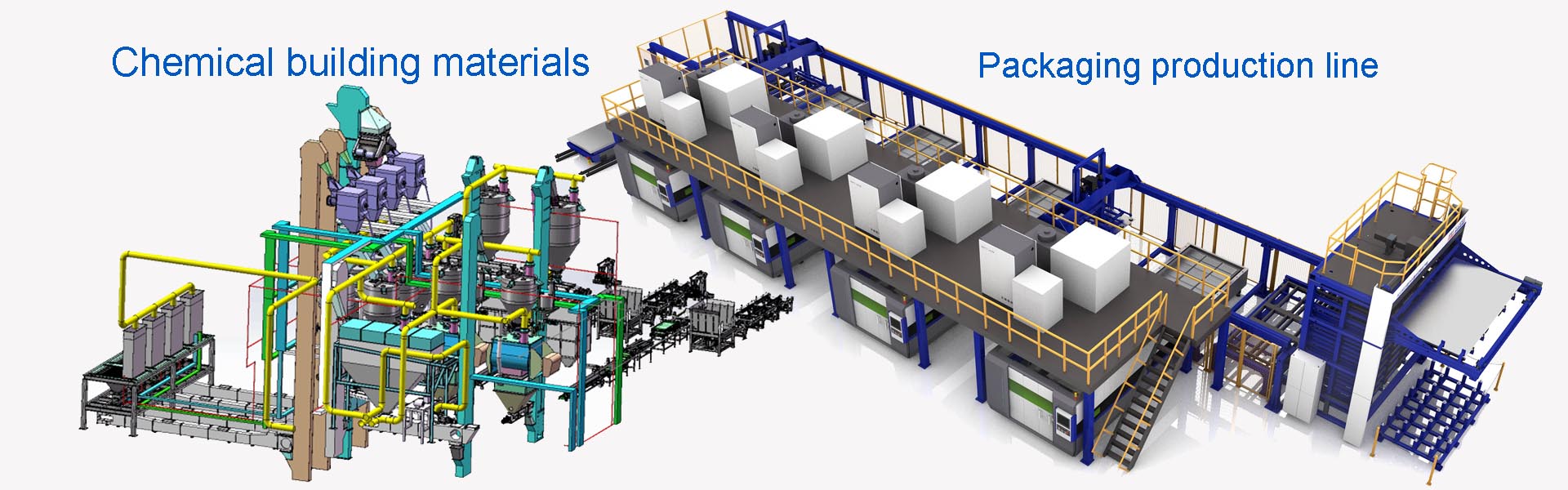

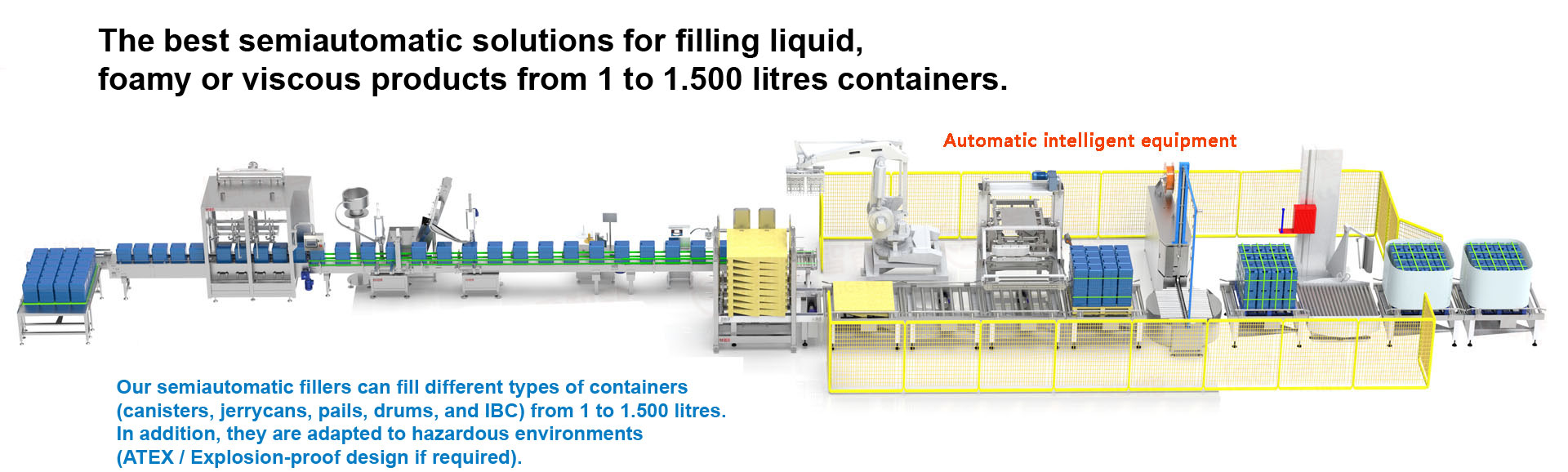

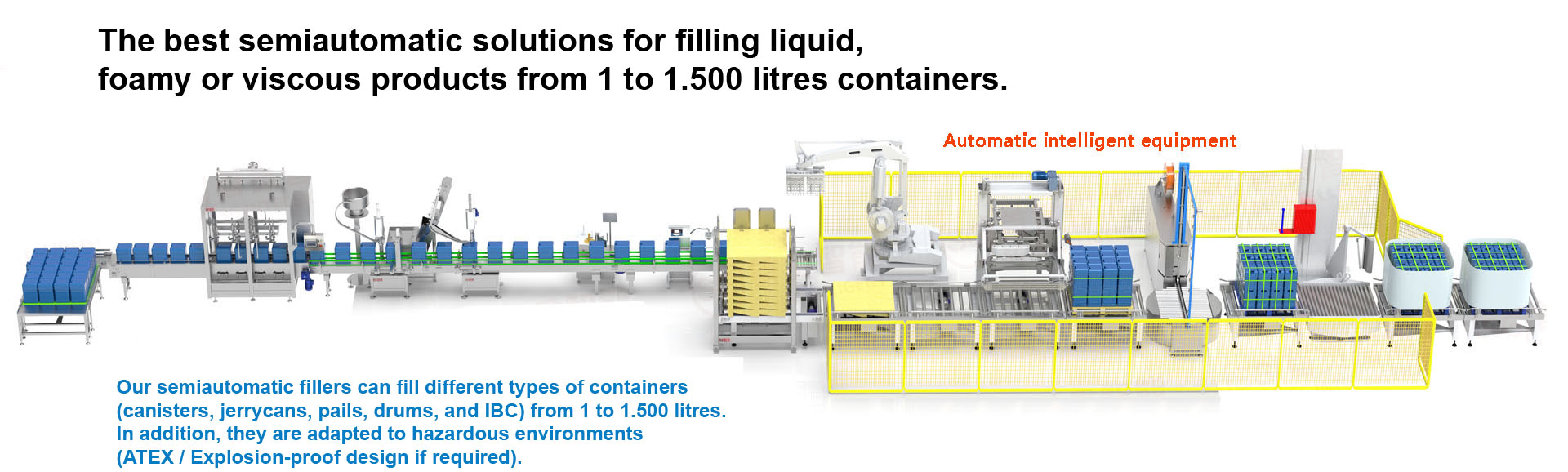

The Automatic Double-Head Liquid Pail Filling Machine is a high-speed, precision filling system designed for engine oil and other viscous liquids. It features dual filling heads for increased productivity, an integrated crown lid sealing mechanism, and robust construction to handle industrial-grade oils. Ideal for 5–20 liter pails, this machine ensures efficient, spill-free filling and secure capping for packaging lines.

Key Features:

Dual Filling Heads:

High Throughput: Two independent filling heads allow simultaneous filling of two pails, doubling productivity.

Synchronized Operation: Automated indexing table moves containers under the heads for seamless workflow.

Engine Oil Compatibility:

Viscosity Handling: Designed for oils up to 10,000 cP (customizable for higher viscosities).

Temperature Control (Optional): Heated jackets or inline heaters to maintain optimal flow at low temperatures.

Precision Filling:

Weight-Based Accuracy: ±0.1% accuracy using load cells to ensure consistent fill levels.

Drift-Free Nozzles: Prevent dripping after filling to minimize waste and contamination.

Adjustable Fill Speeds: Control flow rate to reduce splashing and foaming.

Integrated Crown Lid Sealing:

Automated Capper: Seals crown lids immediately after filling to prevent contamination.

Torque Control: Customizable tightening force for secure closure without over-tightening.

Lid Feeder (Optional): Automatically feeds and aligns crown lids for hands-free operation.

Safety & Compliance:

ATEX/IECEx Options: Explosion-proof models available for hazardous environments (e.g., flammable solvents).

Overfill Protection: Automatically stops filling if preset weight is exceeded.

Emergency Stop Function: Instantly halts operation in case of emergencies.

User-Friendly Operation:

Touchscreen HMI: Intuitive interface for setting parameters, monitoring batches, and troubleshooting.

Foot Pedal Control: Manual start/stop for flexibility during operation.

Pre-Programmed Recipes: Store multiple fill settings for different oil types or container sizes.

Durability & Compatibility:

Corrosion-Resistant Materials: Stainless steel (304/316), PTFE, and chemical-resistant elastomers.

IP65 Rating: Dust and water resistance for harsh industrial environments.

Nitrogen Blanketing (Optional): Inert gas purging to prevent oxidation or foaming.

Foam Management:

Anti-Foam Nozzles: Minimize air entrapment during filling.

Vacuum Filling (Optional): Reduces foam and splashing for highly viscous oils.

Customization Options:

Labeling Integration (Optional): Apply barcodes, batch numbers, or expiration dates.

Conveyor Systems (Optional): Automate container loading/unloading and transport between processes.

Technical Specifications:

Filling Range: 5–20 liters (customizable for larger volumes).

Accuracy: ±0.1% of target weight.

Nozzle Type: Drift-free, self-purging, stainless steel nozzles.

Materials: Stainless steel (304/316), PTFE, and chemical-resistant plastics.

Viscosity Handling: Up to 10,000 cP (optional pump upgrades for higher viscosities).

Environment Rating: IP65 (dust and water resistant).

Compliance: CE certified; ATEX/IECEx options available for hazardous areas.

Applications:

Engine Oils: Conventional, synthetic, and high-viscosity oils.

Industrial Lubricants: Hydraulic fluids, gear oils, and greases.

Greases & Waxes: Highly viscous products requiring precise dosing.

Chemicals: Solvents, adhesives, and corrosive liquids (with optional explosion-proof model).

Operation Steps:

Container Placement: Pails are manually placed or loaded via conveyor onto the indexing table.

Nozzle Positioning: Filling heads descend into the pail to minimize splashing.

Filling: The machine fills to the preset weight using load cells.

Crown Lid Sealing: The automated capper applies and tightens the crown lid.

Container Removal: Filled and sealed pails are removed manually or via conveyor (optional).

Cleanup (Optional): Nozzles self-purge or undergo manual cleaning.

Benefits:

High Efficiency: Dual filling heads and automated capping reduce cycle time and increase output.

Precision: Weight-based filling ensures accurate dosing, minimizing overfilling and material costs.

Versatility: Suitable for engine oils, greases, chemicals, and more with optional customization.

Ease of Use: Touchscreen HMI, foot pedal control, and pre-programmed recipes simplify operation.

Low Maintenance: Tool-free cleaning and durable components minimize downtime.

Customization: Nitrogen blanketing, labeling, and conveyor integration enhance functionality.

Why Choose This Machine?

This double-head filling machine combines speed, precision, and automation into a reliable solution for engine oil and viscous liquid packaging. With its integrated crown lid sealing, temperature control options, and robust construction, it’s ideal for high-volume production lines. Its user-friendly design and customization options make it a top choice for industries requiring efficient, spill-free filling and secure capping.

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Metering and Filling Machine for Filling 1-30L Gel/Isooctyl Acetate[2025-04-01]

-

High Efficiency Filling Machines 5 Gallon Pail Filling Equipment for Chemical Materials[2025-04-29]

-

Explosion Proof Automaticfilling Machine for 30L Glues Cans Stock[2025-05-10]

-

Automatic Bucket Filling Machine for 18L Filling Paste/Paint/Water-Based Paint[2025-07-04]