.Semi-Automatic Explosion-Proof 25L Paint Filling Machine with Crown Lid

Semi-Automatic Explosion-Proof 25L Paint Filling Machine with Crown Lid

Overview

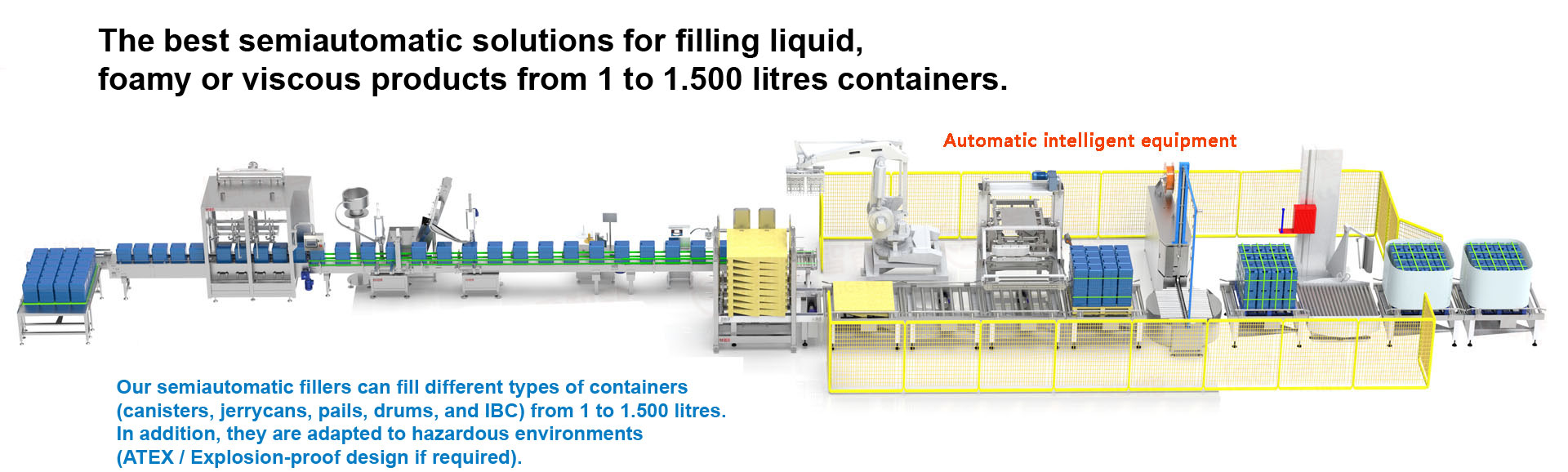

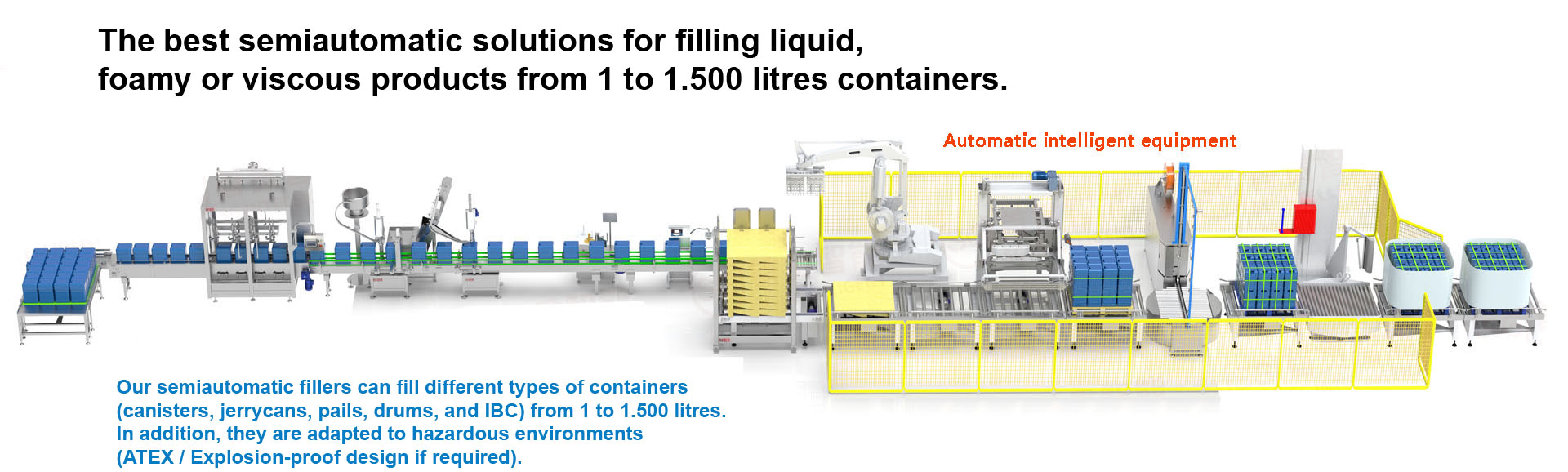

The Semi-Automatic Explosion-Proof 25L Paint Filling Machine is designed for safe and precise filling of flammable or hazardous liquids, such as paints, solvents, adhesives, and chemicals, into 25-liter containers. It features an explosion-proof (ATEX/NEMA) design, a crown lid sealing system, and semi-automatic operation to ensure efficiency, safety, and compliance with industry standards. Below is a detailed breakdown of its features, benefits, and applications.

Key Features

Explosion-Proof Design:

ATEX/NEMA Compliance: Rated for use in hazardous environments (e.g., Zone 1/21 or Zone 2/22).

Flame-proof motors, electrical components, and pneumatic systems prevent ignition of flammable fumes.

Stainless steel construction with anti-static materials to minimize spark risks.

Semi-Automatic Operation:

Operator-controlled filling process with hands-free operation via foot pedal or manual lever.

Adjustable fill volumes and speeds for flexibility in handling different products.

Optional programmable logic controller (PLC) for automated cycles.

25L Container Compatibility:

Designed for filling 25-liter cans, drums, or pails with precision.

Quick changeover between container sizes with tool-free adjustments.

Crown Lid Sealing System:

Integrated crimping mechanism for secure sealing of crown lids.

Ensures airtight closure to prevent leaks, contamination, or evaporation.

Compatible with standard 25L crown lids.

High Accuracy:

Precision flow meters or load cells ensure ±0.5% accuracy in fill volume.

Drip-free nozzles and anti-splash designs minimize product waste and spills.

Safety Features:**

Spill containment trays and emergency stop buttons for operator safety.

Grounding clamps and static dissipation systems to prevent static buildup.

Fume extraction ports to reduce operator exposure to harmful vapors.

Hygienic and Corrosion-Resistant Materials:

Constructed from 304/316 stainless steel and chemical-resistant alloys.

PTFE or Viton seals for compatibility with aggressive chemicals.

Easy-to-clean components for maintenance and compliance with hygiene standards.

User-Friendly Interface:

Touchscreen HMI (Human-Machine Interface) for intuitive operation and recipe management.

Pre-programmable fill volumes, speeds, and cycle times for different products.

Durability and Low Maintenance:

Self-priming pumps and robust construction ensure long lifespan.

Minimal wear parts and easy access to critical components for quick maintenance.

Applications

Paint and Coatings Industry:

Filling 25L containers with water-based or solvent-based paints, varnishes, or coatings.

Safe handling of flammable or combustible liquids.

Chemical Manufacturing:

Filling drums with adhesives, resins, solvents, or other hazardous chemicals.

ATEX compliance ensures safe operation in explosive atmospheres.

Oil and Lubricants:

Filling 25L containers with engine oils, lubricants, or greases.

Crown lid sealing prevents leaks and contamination.

Food Grade Applications:

Filling edible oils, food additives, or other food-grade liquids into 25L containers.

Stainless steel and food-safe materials ensure compliance with hygiene standards.

Pharmaceuticals and Nutraceuticals:

Filling containers with syrups, oral liquids, or viscous pharmaceutical formulations.

GMP-compliant design ensures traceability and contamination control.

Benefits

Safety:

Explosion-proof design ensures safe operation in hazardous environments.

ATEX/NEMA compliance meets international safety standards.

Precision:

High-accuracy filling minimizes product waste and ensures consistent quality.

Adjustable parameters accommodate different products and container sizes.

Efficiency:

Semi-automatic operation reduces labor costs and increases throughput.

Quick changeover between container sizes minimizes downtime.

Cost Effectiveness:

Minimizes product loss and reduces material costs.

Low maintenance requirements due to durable construction and easy-to-clean components.

Flexibility:

Customizable pumps, nozzles, and flow meters for diverse applications.

Easily integrated into existing workflows or expanded as needed.

Compliance:

CE and ATEX certifications ensure compliance with EU safety and environmental regulations.

Hygienic design and food-grade materials meet industry standards.

Customization Options

Flow Meter/Load Cell: High-precision flow meters or load cells for accurate filling.

Pump Options: Centrifugal pumps, gear pumps, or diaphragm pumps for viscous liquids.

Nozzle Designs: Foam-reducing, bottom-up filling, or splash-proof nozzles for specific applications.

Safety Features: ATEX/NEMA-rated components, static grounding, and spill containment.

Materials: Stainless steel, PTFE, or chemical-resistant alloys for corrosive products.

Automation Add-Ons: Conveyor systems, labeling equipment, or data logging for traceability.

Environmental Control: Vacuum or nitrogen blanketing to prevent oxidation or contamination.

IoT Connectivity: Remote monitoring and troubleshooting for predictive maintenance.

Conclusion

The Semi-Automatic Explosion-Proof 25L Paint Filling Machine with Crown Lid is a reliable, efficient, and safe solution for filling hazardous or flammable liquids into 25-liter containers. Its explosion-proof design, precision, and customizable features make it ideal for paint manufacturing, chemical processing, pharmaceuticals, and industrial applications. By investing in this machine, businesses can ensure consistent product quality, reduce costs, and maintain compliance with strict safety and environmental standards.

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automated, High-Speed Oil & Lubricant Fillers Precision Drum & Tote Filling Systems[2025-06-18]

-

Automatic Body Shampoo Filling and Capping Machine Liquid Filling Machine[2025-05-22]

-

Chemical Raw Material Liquid Drum Weighing Filling Machine for 100L/200L/300L/400L[2025-07-04]

-

Body Lotion Sunscreen Cream Plastic Glass Jar Automatic Filler Machine[2025-06-12]