Automatic Liquid Pail Filling Machine for Real Stone Paint High Efficiency and Precision, Stainless Steel, Simple Operation

Automatic Liquid Pail Filling Machine for Real Stone Paint: High Efficiency, Precision, and Simplicity

Overview

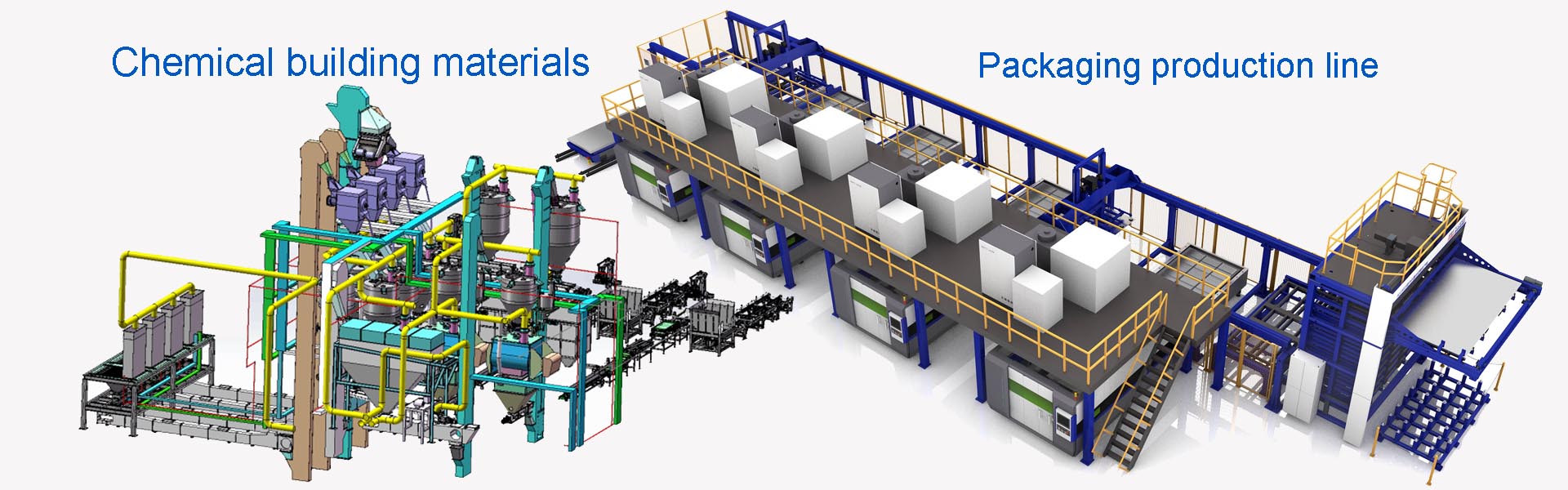

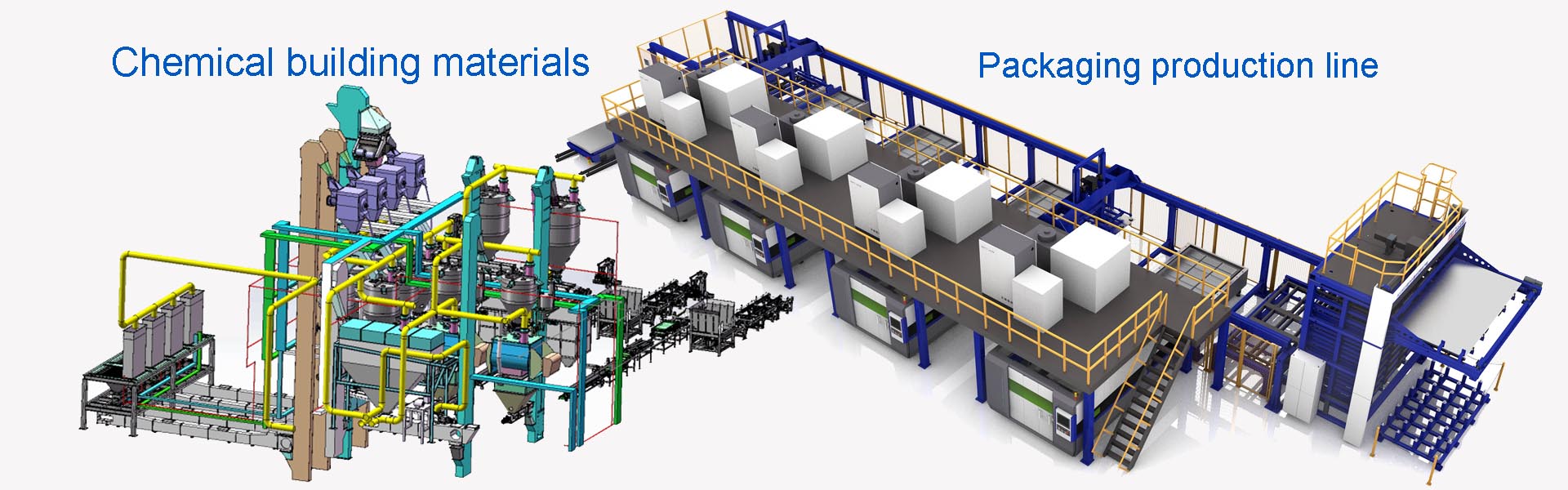

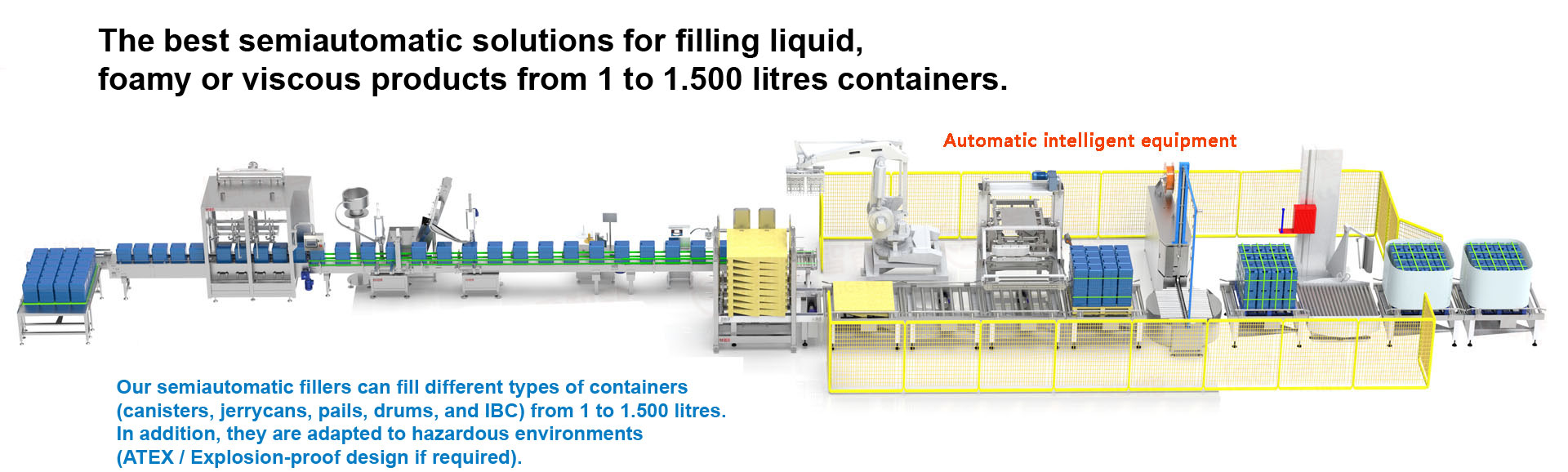

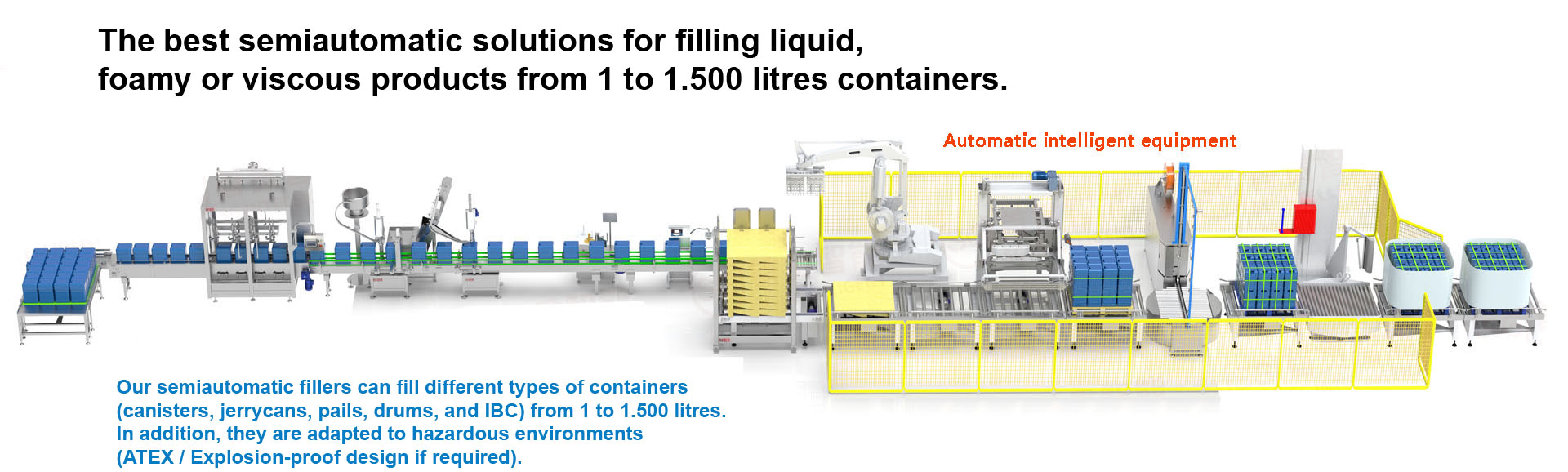

The automatic liquid pail filling machine is designed for high-efficiency, precise filling of real stone paint and other viscous or hazardous liquids into pails. With a stainless steel construction, user-friendly interface, and ATEX/IECEx certification for explosive atmospheres, this machine ensures safety, accuracy, and productivity in industrial settings. It’s ideal for medium to large-scale production of real stone paint, coatings, adhesives, and more.

Key Features

High Efficiency

Fast Filling Speeds: Up to 60–120 pails/hour (dependent on product viscosity and container size).

Continuous Operation: Automated loading, filling, and unloading reduce manual labor and cycle times.

Precision Filling

±0.5% Accuracy: Ensures consistent fill volumes with no overfilling or underfilling.

Weight-Based Control: Integrated load cells measure and adjust fill volumes in real time.

Stainless Steel Construction

304/316 Stainless Steel: Corrosion-resistant and easy to clean, suitable for aggressive chemicals.

Hygienic Design: Sealed components prevent contamination and leaks.

Simple Operation

Touchscreen HMI: Intuitive controls for setting fill parameters, batch counts, and recipes.

Automated Functions: Automatic container detection, filling, and stop-and-go functionality.

Minimal Training Required: Operators can start with basic training.

Safety & Compliance

Explosion-Proof Certification: ATEX/IECEx compliant for Zone 1/21 hazardous environments.

Static Grounding: Eliminates spark risks during filling.

Emergency Stop: Redundant safety features for immediate shutdown.

Versatility

Container Sizes: Compatible with 1–5 gallon pails (customizable for larger sizes).

Product Compatibility: Suitable for high-viscosity liquids (e.g., real stone paint), solvents, and resins.

Optional Capping: Integrated automatic crown lid sealing (available as an add-on).

Technical Specifications

Filling Range: 1–5 gallons (adjustable).

Speed: 60–120 pails/hour (dependent on viscosity and container size).

Accuracy: ±0.5% of target weight.

Materials: 304/316 stainless steel (food-grade optional).

Power: 220V/50Hz or 110V/60Hz (energy-efficient).

Certifications: ATEX/IECEx, CE, ISO.

Operation Steps

Load Pails: Place empty pails on the conveyor or loading station.

Set Parameters: Use the touchscreen to select fill volume, speed, and batch size.

Automated Filling: The machine detects the pail, fills it to the target weight, and moves to the next container.

Unload & Seal: Filled pails are discharged onto a conveyor for optional capping or labeling.

Applications

Real Stone Paint: Viscous, solvent-based coatings for decorative concrete.

Industrial Coatings: Epoxy, polyurethane, and high-solids formulations.

Adhesives & Resins: High-viscosity liquids requiring precise measurement.

Hazardous Chemicals: Flammable solvents, thinners, and oils in explosive environments.

Benefits

Maximized Productivity: High-speed filling with minimal downtime increases output.

Precision & Consistency: Accurate fill volumes reduce material waste and ensure product quality.

Safety Compliance: ATEX/IECEx certification and spark-resistant design meet global safety standards.

Low Maintenance: Stainless steel construction and durable components minimize long-term costs.

User-Friendly: Touchscreen controls and automated functions simplify operation for all skill levels.

Why Choose This Machine?

This automatic liquid pail filling machine delivers unmatched efficiency, precision, and safety for real stone paint and hazardous liquids. Its stainless steel build, ATEX compliance, and easy operation make it perfect for industrial applications. Whether you’re scaling production or upgrading equipment, this machine offers long-term reliability and value with minimal complexity.

Contact us today for a customized quote or demo!

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com