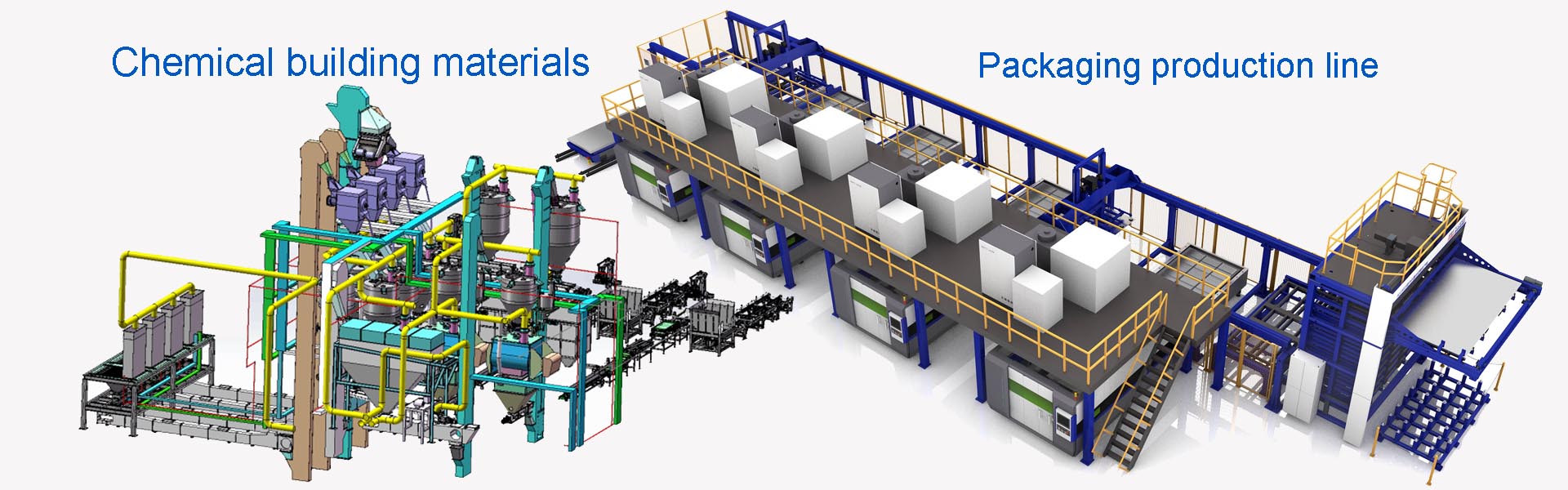

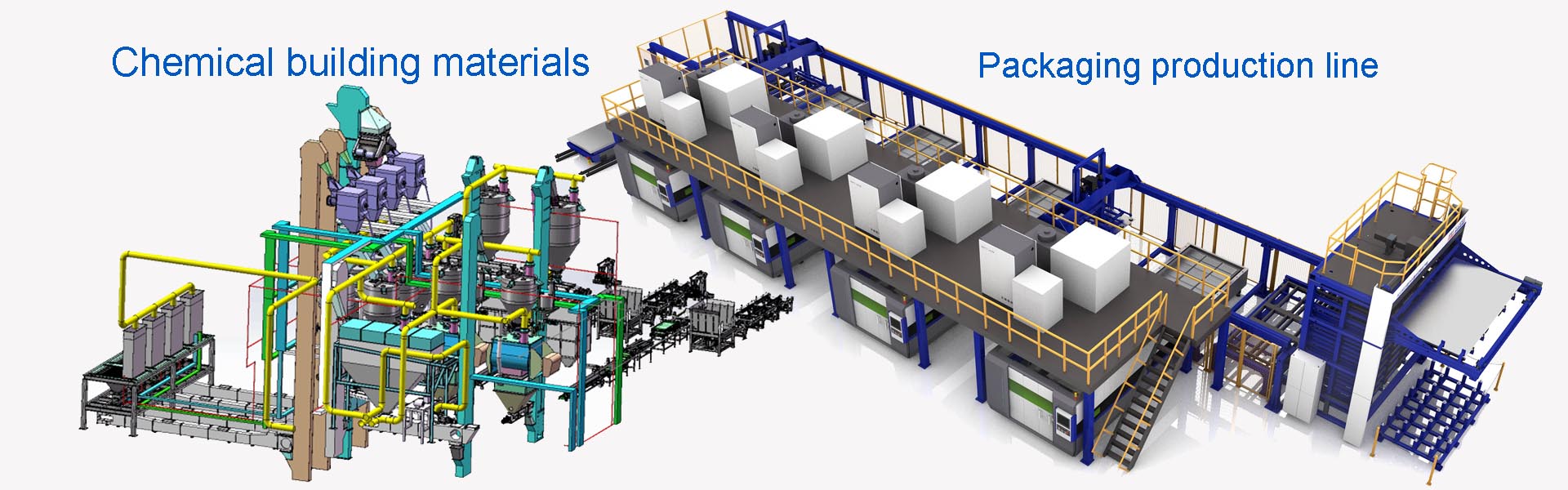

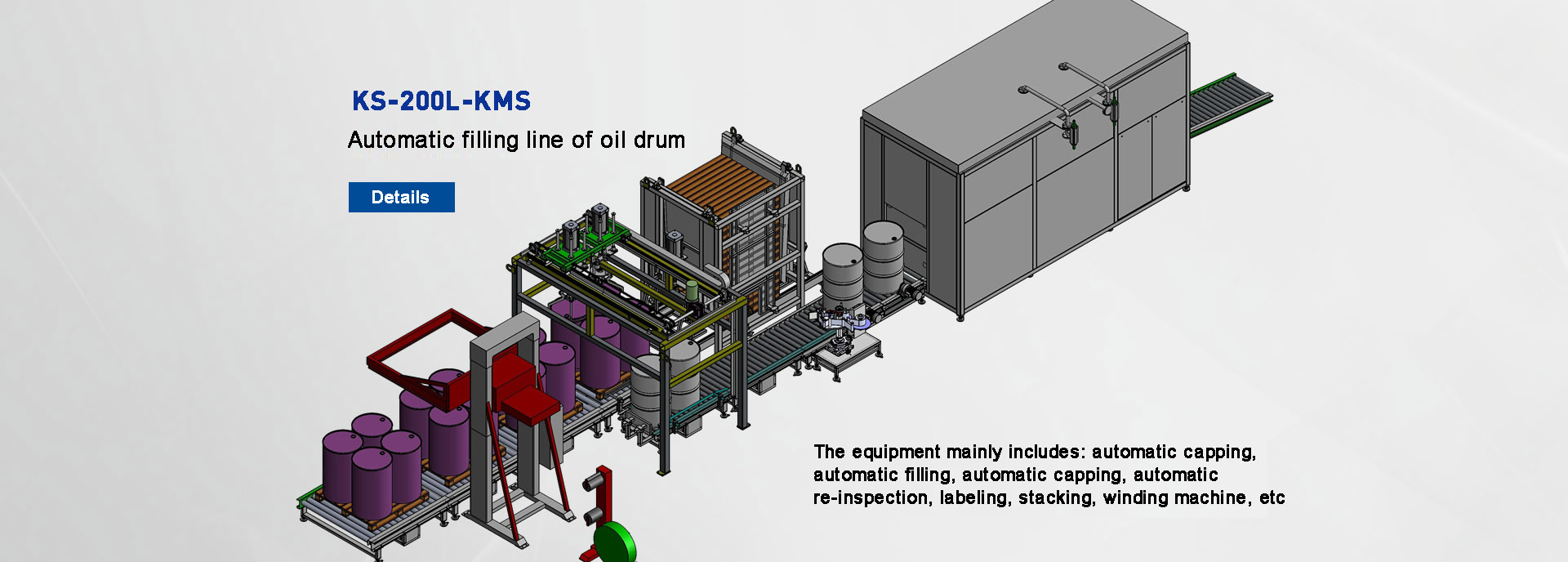

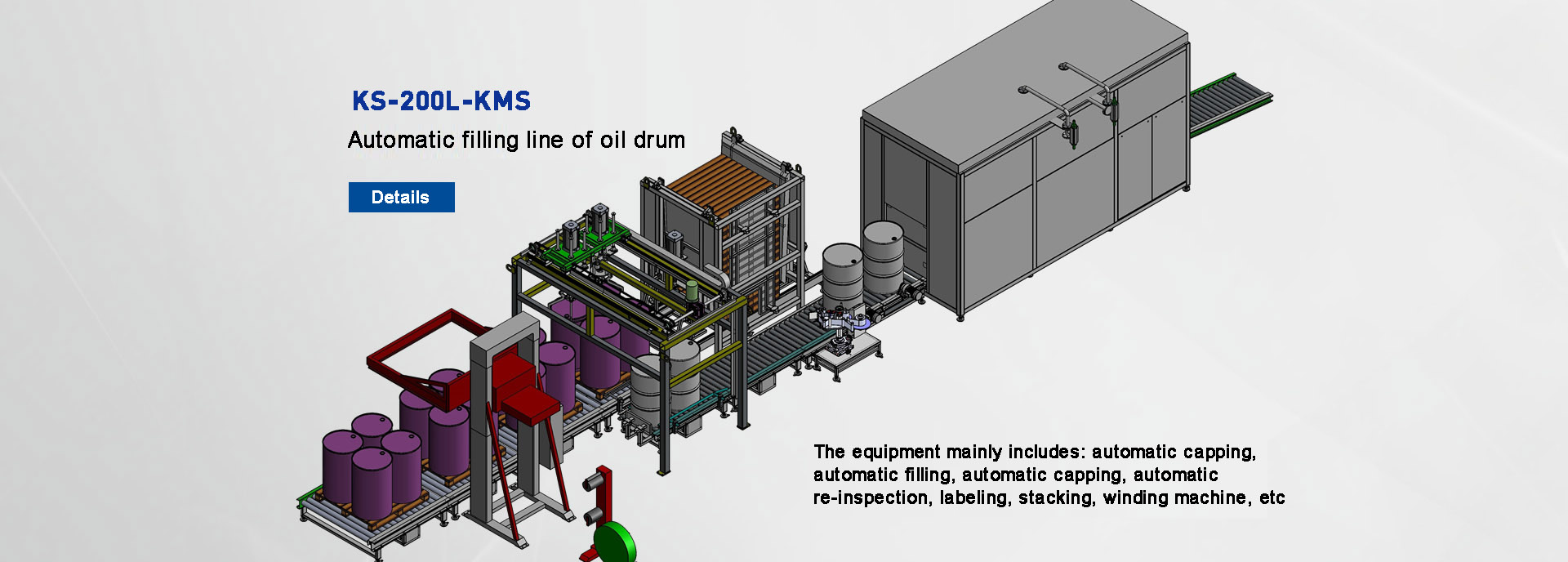

Liquid Surface Pallet Packaging Machine, 200kg Real Stone Paint Packaging Machine Factory

The Liquid Surface Pallet Packaging Machine and 200kg Real Stone Paint Packaging Machine are specialized industrial equipment designed for efficient, high-capacity packaging of liquids, particularly in the paint and coatings industry. Below is a detailed overview of these machines, their applications, features, and benefits:

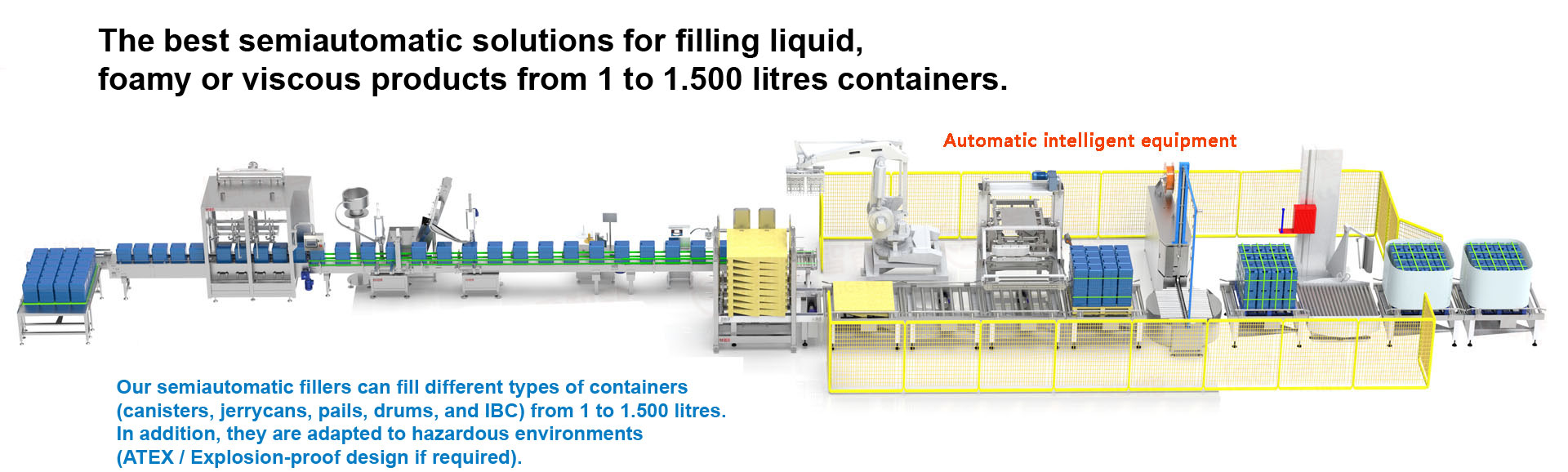

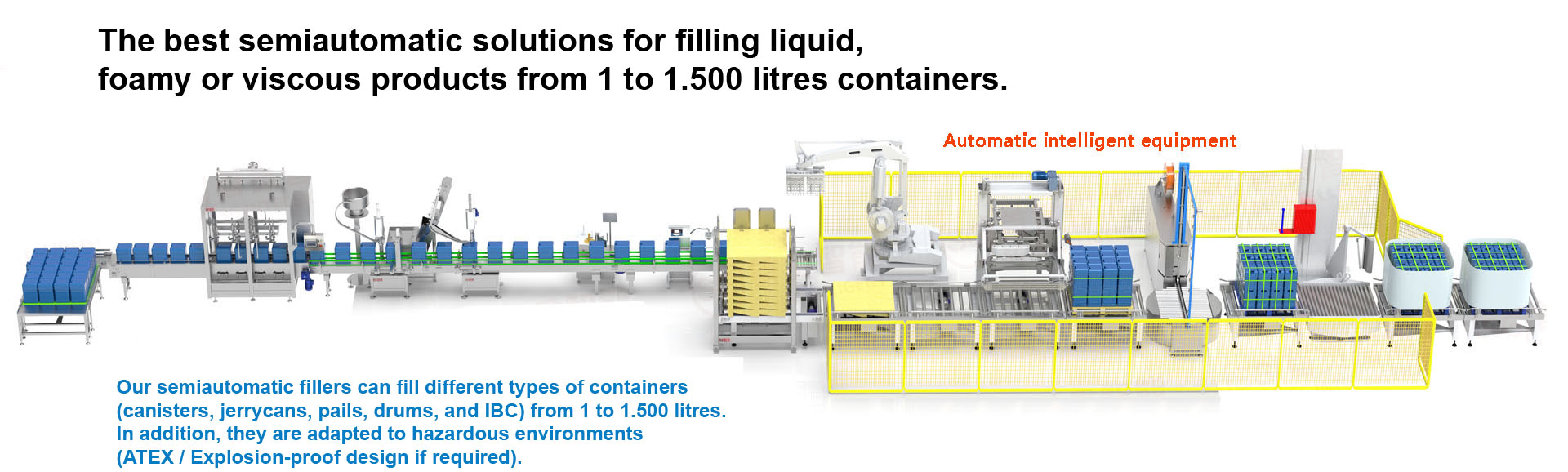

1. Liquid Surface Pallet Packaging Machine

Overview:

This machine is designed for bulk packaging of liquids (e.g., paints, coatings, chemicals) onto pallets, often using intermediate bulk containers (IBCs) or drums. It ensures precise, spill-free dispensing and is ideal for high-volume production environments.

Key Features:

High Capacity:

Designed for bulk packaging, typically handling 200kg or more per container.

Suitable for IBCs, drums, or palletized containers.

Precision Filling:

High-accuracy sensors ensure exact fill levels, minimizing overfilling or underfilling.

Adjustable flow rates for different liquid viscosities.

Drip-Free Design:

Nozzles and seals prevent spillage during filling, ensuring cleanliness and safety.

Ideal for viscous liquids like paints and coatings.

Automation:

Fully automated operation reduces labor costs and increases efficiency.

Integrated conveyor systems for seamless container movement.

Safety Features:

Safety interlocks, emergency stop buttons, and spill containment systems.

Optional explosion-proof design for hazardous environments.

Corrosion-Resistant Construction:

Made from stainless steel or chemical-resistant materials to handle aggressive liquids.

Easy to clean and maintain.

Touchscreen Interface:

Intuitive HMI (Human-Machine Interface) for setting parameters, monitoring fill levels, and accessing recipes.

Adjustable Speed:

Variable speed control for precise filling of different liquids and container sizes.

Applications:

Packaging liquids like paints, coatings, chemicals, and adhesives.

Bulk filling of IBCs, drums, or palletized containers.

Industrial, pharmaceutical, and food-grade liquid packaging.

2. 200kg Real Stone Paint Packaging Machine Factory

Overview:

This machine is specifically designed for packaging high-viscosity products like real stone paint (textured coatings) into 200kg containers. It is tailored for the paint and coatings industry, where precision and efficiency are critical.

Key Features:

High Viscosity Handling:

Engineered to handle thick, viscous products like real stone paint.

Robust motor and pump system ensures smooth dispensing.

200kg Capacity:

Designed for filling 200kg containers or drums.

Suitable for bulk packaging in industrial settings.

Precision Filling:

High-accuracy sensors ensure exact fill levels, minimizing waste.

Adjustable flow rates for different product viscosities.

Drip-Free Design:

Nozzles and seals prevent spillage during filling, ensuring cleanliness and safety.

Ideal for messy or viscous products.

Automation:

Fully automated operation reduces labor costs and increases efficiency.

Integrated conveyor systems for seamless container movement.

Safety Features:

Safety interlocks, emergency stop buttons, and spill containment systems.

Optional explosion-proof design for hazardous environments.

Corrosion-Resistant Construction:

Made from stainless steel or chemical-resistant materials to handle aggressive products.

Easy to clean and maintain.

Touchscreen Interface:

Intuitive HMI (Human-Machine Interface) for setting parameters, monitoring fill levels, and accessing recipes.

Customization Options:

Tailored for real stone paint, but can be adapted for other high-viscosity products.

Optional weighing systems for precise measurement.

Applications:

Packaging real stone paint, textured coatings, and other high-viscosity products.

Bulk filling of 200kg drums or containers.

Industrial paint and coatings manufacturing.

Factory Capabilities:

A factory specializing in these machines would offer:

Customization:

Tailored solutions for specific product viscosities, container sizes, and production requirements.

Optional features like explosion-proof design, integrated capping, or labeling systems.

Technical Support:

On-site installation, training, and maintenance services.

Spare parts and after-sales support.

Quality Assurance:

Compliance with industry standards for safety, accuracy, and environmental protection.

ISO certification and rigorous testing procedures.

Scalability:

Scalable solutions for small, medium, or large-scale production needs.

Benefits:

Efficiency:

Automated operation reduces labor costs and increases production speed.

Accuracy:

High-precision filling minimizes waste and ensures consistent product quality.

Safety:

Protects operators from exposure to hazardous or viscous products.

Versatility:

Suitable for a wide range of liquids and container sizes.

Cost Savings:

Minimizes product waste and reduces labor costs through automation.

Compliance:

Meets industry standards for safety, accuracy, and environmental protection.

Conclusion:

The Liquid Surface Pallet Packaging Machine and 200kg Real Stone Paint Packaging Machine are specialized solutions for efficient, high-capacity packaging of liquids, particularly in the paint and coatings industry. Their precision, safety features, and automation capabilities make them ideal for industrial applications. Whether you need to package viscous products like real stone paint or handle bulk liquids, these machines offer reliability, accuracy, and peace of mind.

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com