High Speed 50kg Dry Mixed Mortar Valve Bag Packing Machine with Bag Drop Device 2

A high-speed 50kg dry mixed mortar valve bag packing machine with a bag drop device is designed for efficient and precise packaging of dry mix mortar into valve bags (also known as sacks or bags). Here’s an overview of its features, functionality, and benefits:

Key Features

High-Speed Packing:

Capable of filling 50kg valve bags at high speeds, significantly increasing production efficiency.

Suitable for large-scale operations in the construction and building materials industry.

Valve Bag Compatibility:

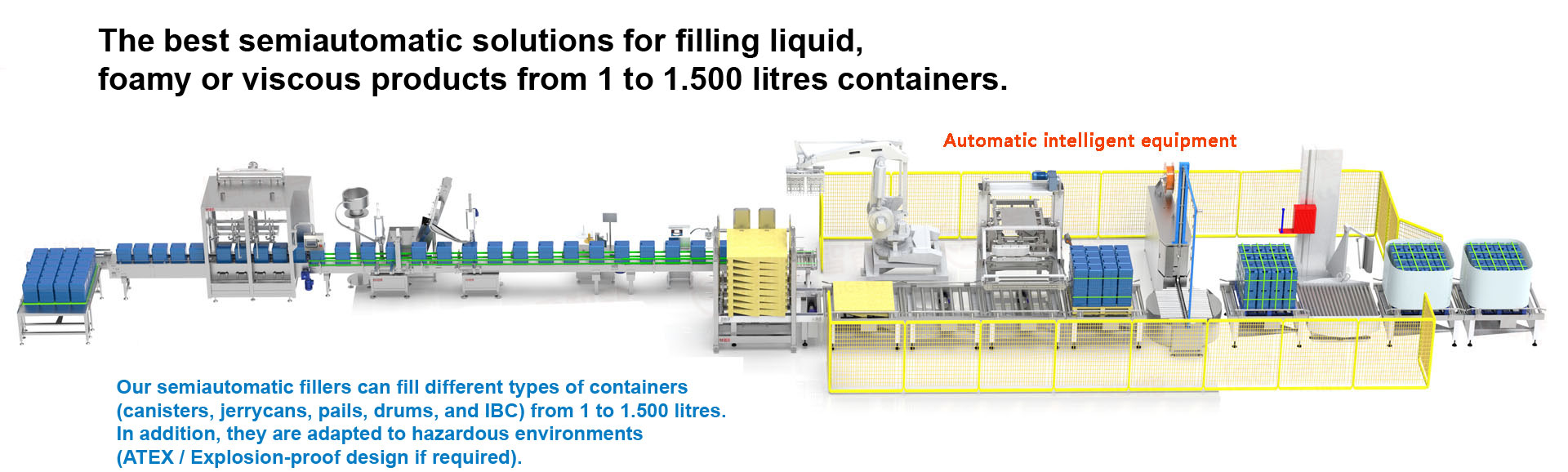

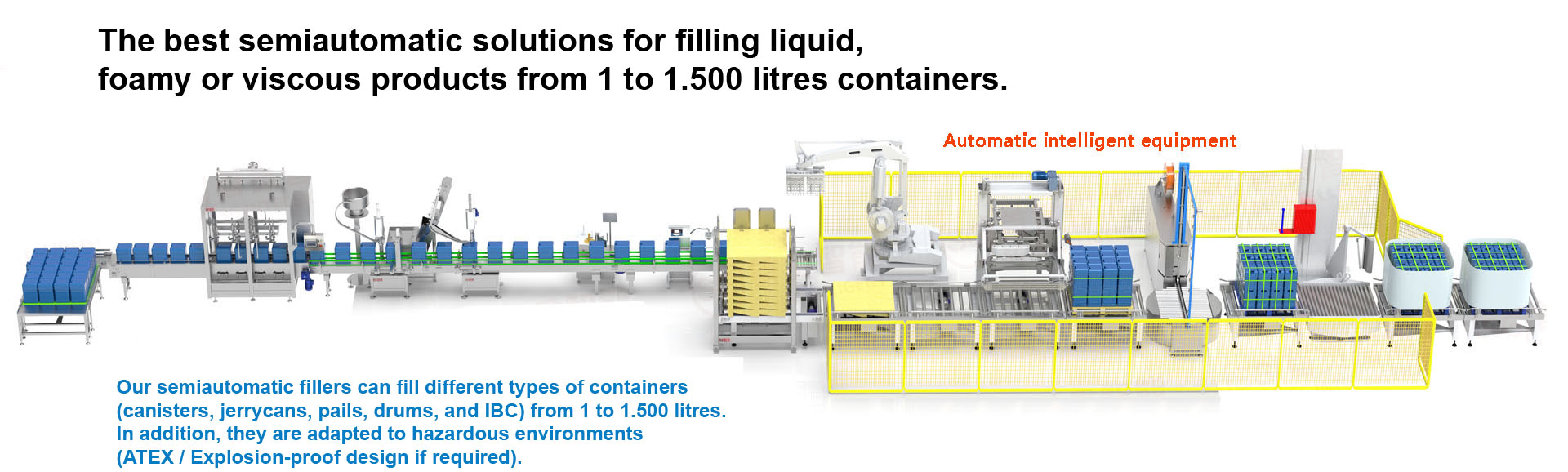

Specifically designed for valve bags, which are sealed at the top and have a spout for easy pouring.

Ensures clean and accurate filling without spillage.

Bag Drop Device:

Automates the process of dropping empty bags into the filling station.

Reduces manual labor and improves workflow efficiency.

Precision Weighing:

Equipped with advanced weighing systems to ensure accurate filling of 50kg per bag.

Minimizes overfilling or underfilling, reducing material waste.

Dust Control:

Incorporates dust extraction systems to minimize airborne particles during the filling process.

Protects the environment and operator health.

User-Friendly Interface:

PLC (Programmable Logic Controller) or HMI (Human-Machine Interface) for easy operation and monitoring.

Allows for quick adjustments to filling parameters.

Durability:

Built with heavy-duty materials (e.g., stainless steel or corrosion-resistant alloys) to withstand harsh industrial environments.

Designed for long-term reliability and low maintenance.

Customization:

Adaptable to different bag sizes and weights (e.g., 25kg, 40kg, or 50kg).

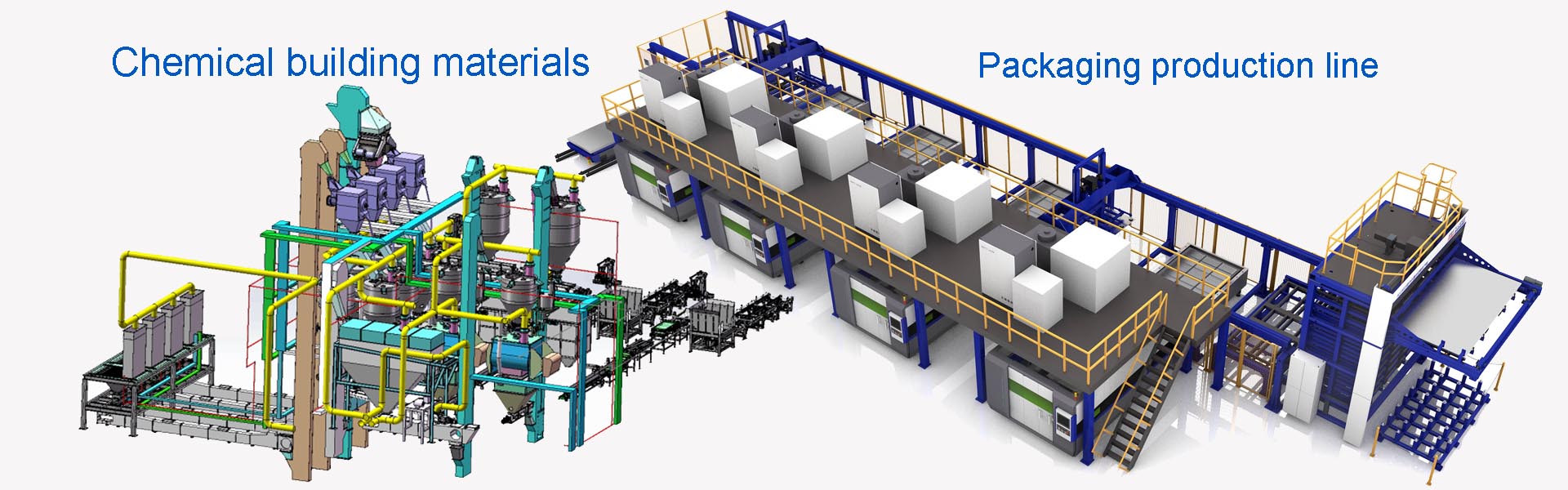

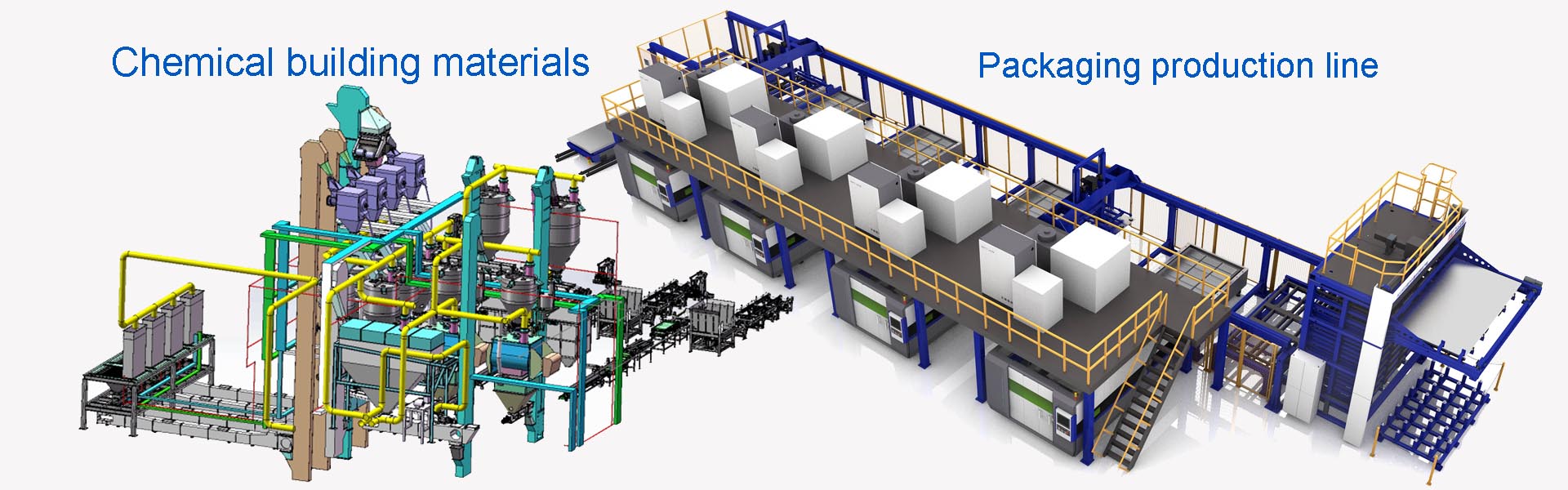

Can be integrated with upstream processes like mixing or conveying systems.

Benefits

Increased Productivity: High-speed operation and automated bag handling reduce cycle times and boost output.

Cost Efficiency: Minimizes labor costs and material waste, maximizing profitability.

Consistency: Precision filling ensures uniform quality in every bag.

Safety: Dust control and automation reduce operator exposure to hazardous materials.

Scalability: Suitable for small-scale or large-scale production needs.

Applications

Dry mix mortar production.

Cement and sand packaging.

Construction materials manufacturing.

Industrial powders and granular materials.

How It Works

Bag Drop: The bag drop device automatically feeds empty valve bags into the filling station.

Filling: The machine precisely fills each bag with 50kg of dry mixed mortar.

Sealing: The valve bag is sealed manually or automatically after filling.

Dispensing: Filled bags are discharged onto a conveyor for further handling or palletizing.

Technical Specifications

Capacity: 50kg per bag (customizable).

Speed: High-speed operation (e.g., 10-20 bags per minute, depending on the model).

Material: Stainless steel or corrosion-resistant alloys.

Control System: PLC or HMI for automated operation.

Power Requirements: Industrial-grade electrical supply.

This machine is ideal for manufacturers seeking to optimize their dry mix mortar packaging process, improve productivity, and maintain high standards of accuracy and safety.

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com