High-Precision 25kg Manual Filling Machine for Efficient Packaging

The High-Precision 25kg Manual Filling Machine is a versatile and cost-effective solution designed for accurate, reliable, and user-friendly bulk packaging of granules, powders, pellets, and similar free-flowing materials into 25kg containers. Ideal for industries such as chemicals, food processing, agriculture, construction, and pharmaceuticals, this machine combines precision engineering with intuitive operation to enhance productivity while minimizing waste and operator fatigue.

Key Features & Benefits

Unmatched Filling Accuracy

Advanced weighing system with high-precision load cells (accuracy ±0.1%–0.2% of target weight).

Auto-tare and zero-tracking functions ensure consistent filling without over/under-dosing.

Adjustable target weights (customizable beyond 25kg for flexibility).

User-Centric Design

Ergonomic manual control panel with digital display for easy weight setting and real-time monitoring.

Quick-release container holder for effortless loading/unloading of bags, drums, or sacks.

Dust-tight construction with optional dust collection ports to maintain a clean workspace.

Durable & Low-Maintenance Build

Robust stainless steel (SS304/SS316) frame and contact parts for corrosion resistance and hygiene.

Modular design allows for easy cleaning, part replacement, and upgrades.

Minimal moving parts reduce maintenance needs and downtime.

Versatile Material Compatibility

Suitable for a wide range of materials, including fertilizers, plastic resins, flour, sugar, detergents, and more.

Optional vibratory feeders or auger systems for handling non-free-flowing or sticky products.

Cost-Effective Efficiency

Faster filling cycles compared to manual scooping or weighing (up to 8–12 bags/hour, depending on material).

Reduces labor costs and material waste through automated precision.

Low energy consumption and compact footprint for space-saving operation.

Technical Specifications

| Parameter | Details |

|---|---|

| Filling Capacity | 5kg–50kg (standard: 25kg) |

| Accuracy | ±0.1%–0.2% of target weight |

| Filling Speed | 8–12 bags/hour (material-dependent) |

| Power Supply | 110V/220V, 50/60Hz, single-phase |

| Weighing Platform | Stainless steel, IP65-rated |

| Display | High-resolution LED/LCD with backlight |

| Construction Material | SS304 (optional SS316 for harsh environments) |

Applications

Chemical Industry: Filling of fertilizers, pesticides, and powdered additives.

Food & Beverage: Packaging of flour, spices, sugar, and coffee.

Pharmaceuticals: Dispensing of powdered ingredients or granules.

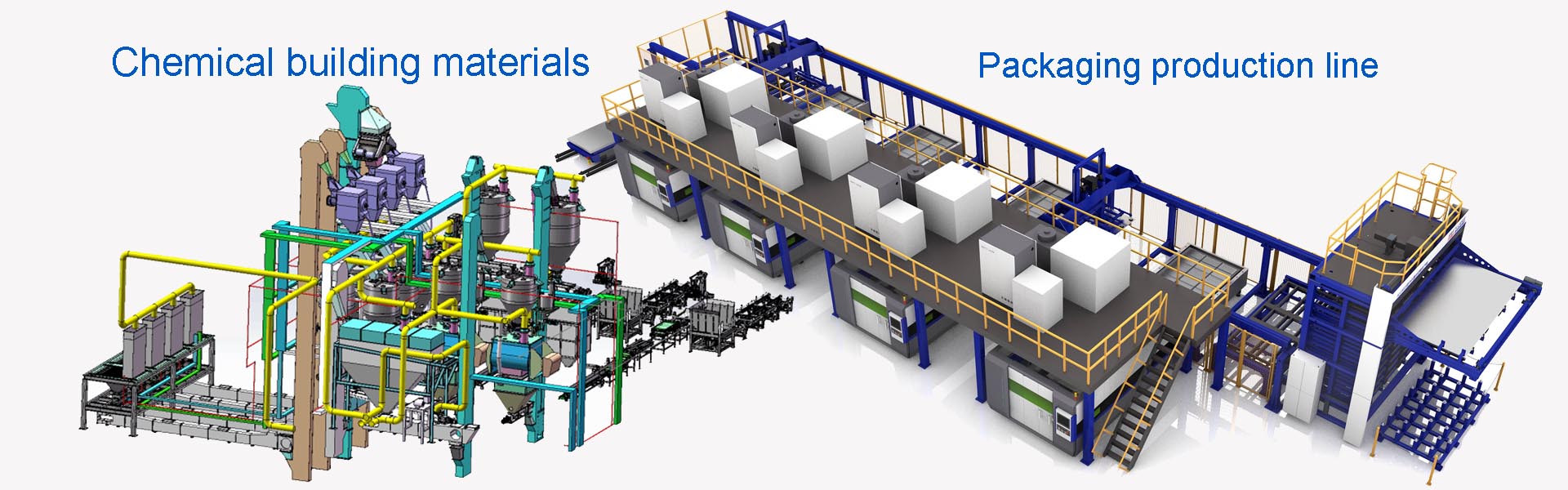

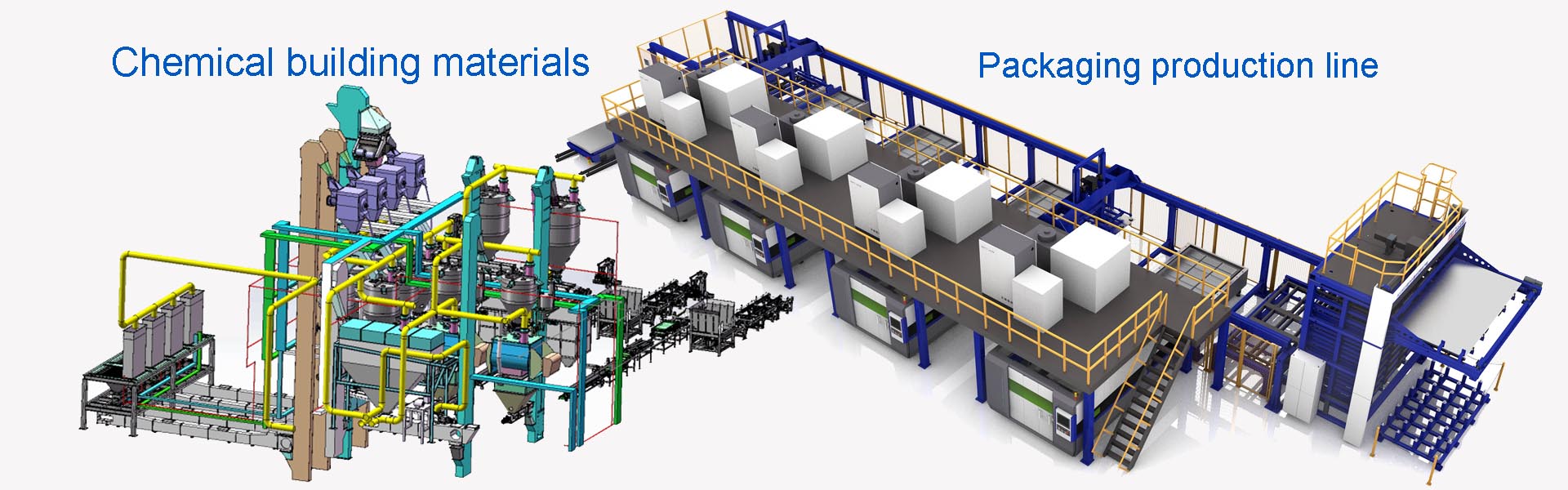

Construction: Bulk packaging of cement, sand, or plaster mixes.

Agriculture: Seed, feed, and grain packaging.

Why Choose Our Machine?

Precision Guaranteed: Eliminates human error in weighing, ensuring compliance with quality standards.

Ease of Use: Train operators in minutes with its straightforward controls and minimal setup.

Affordable Excellence: High ROI through reduced material waste and labor costs.

Global Compliance: Meets CE, FDA, and ISO standards for safety and hygiene.

APPLICABLE BARREL TYPE

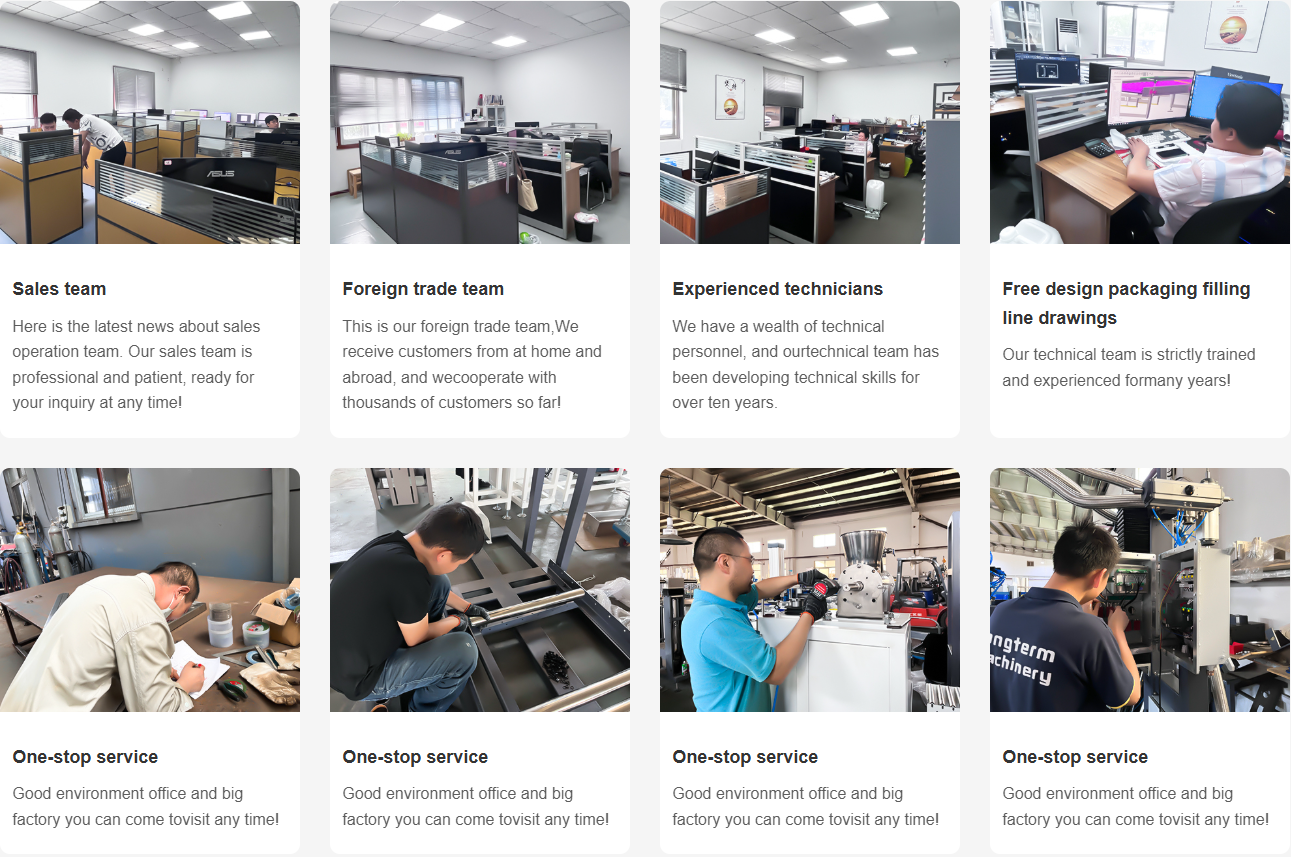

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

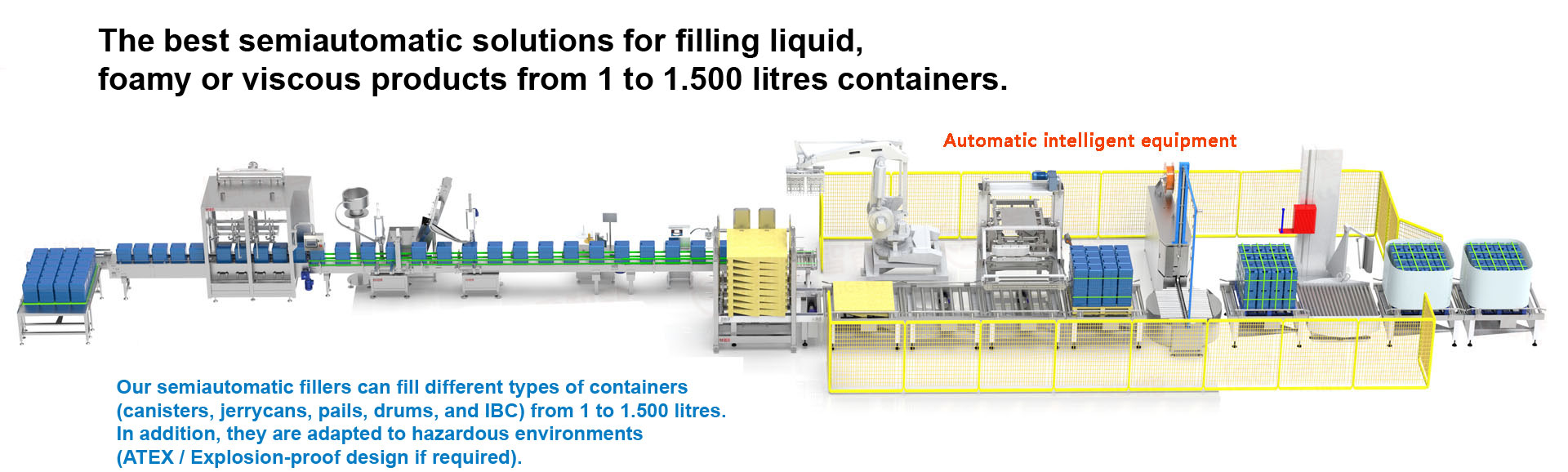

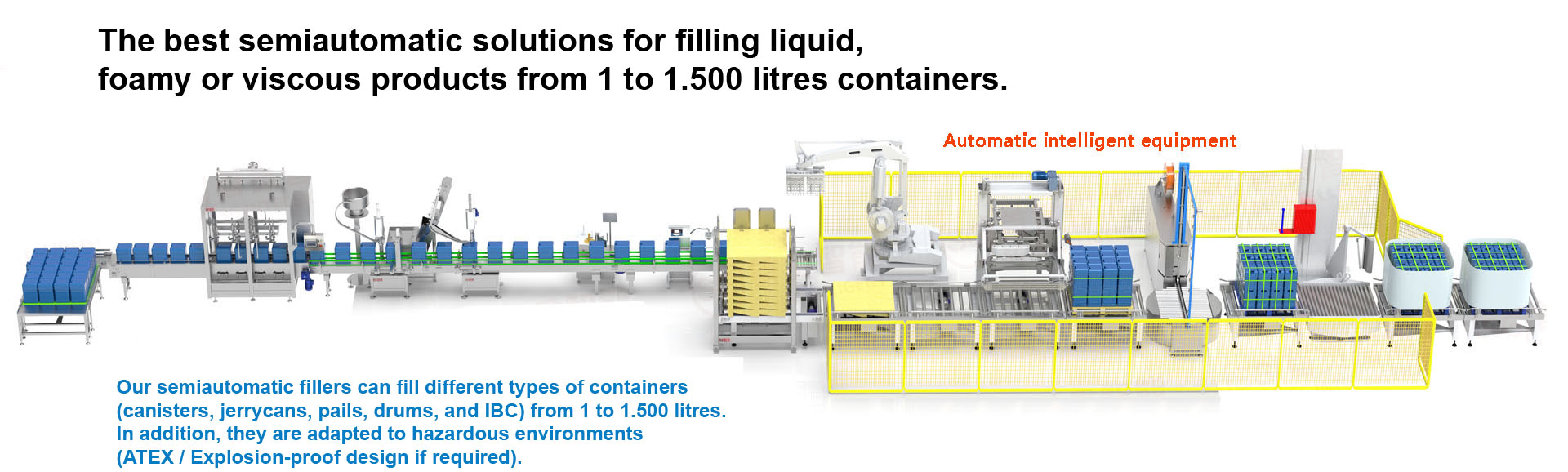

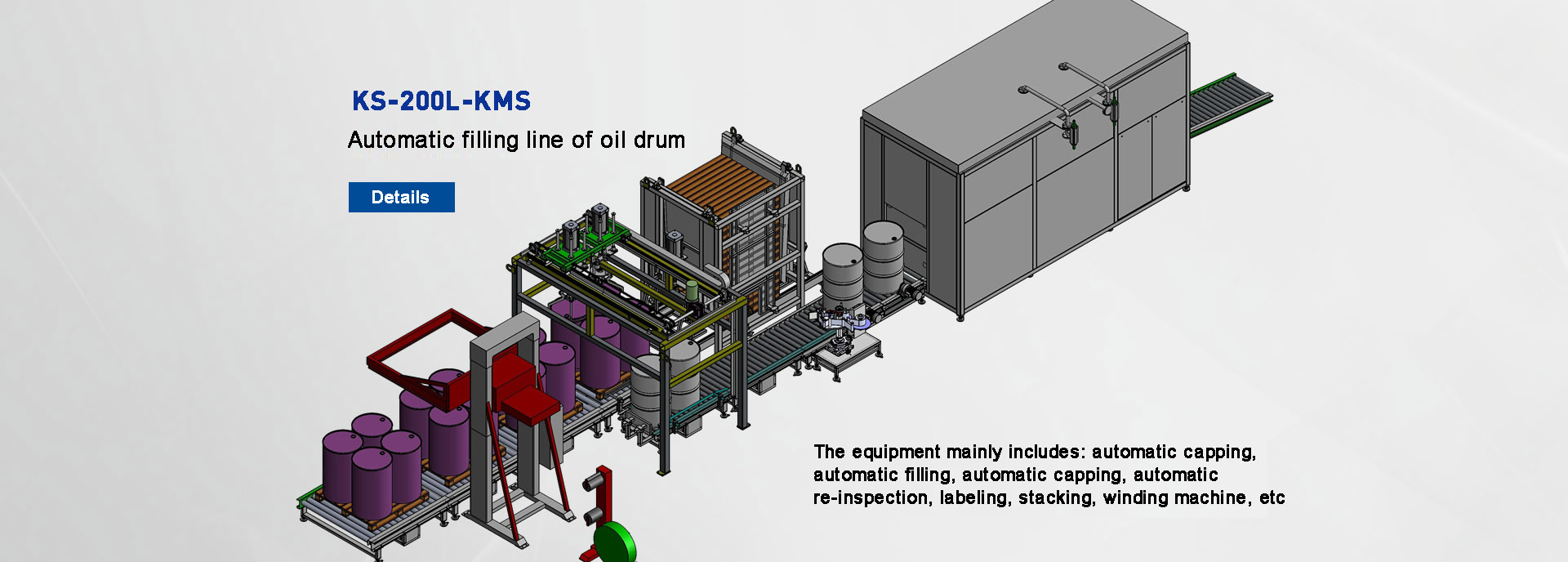

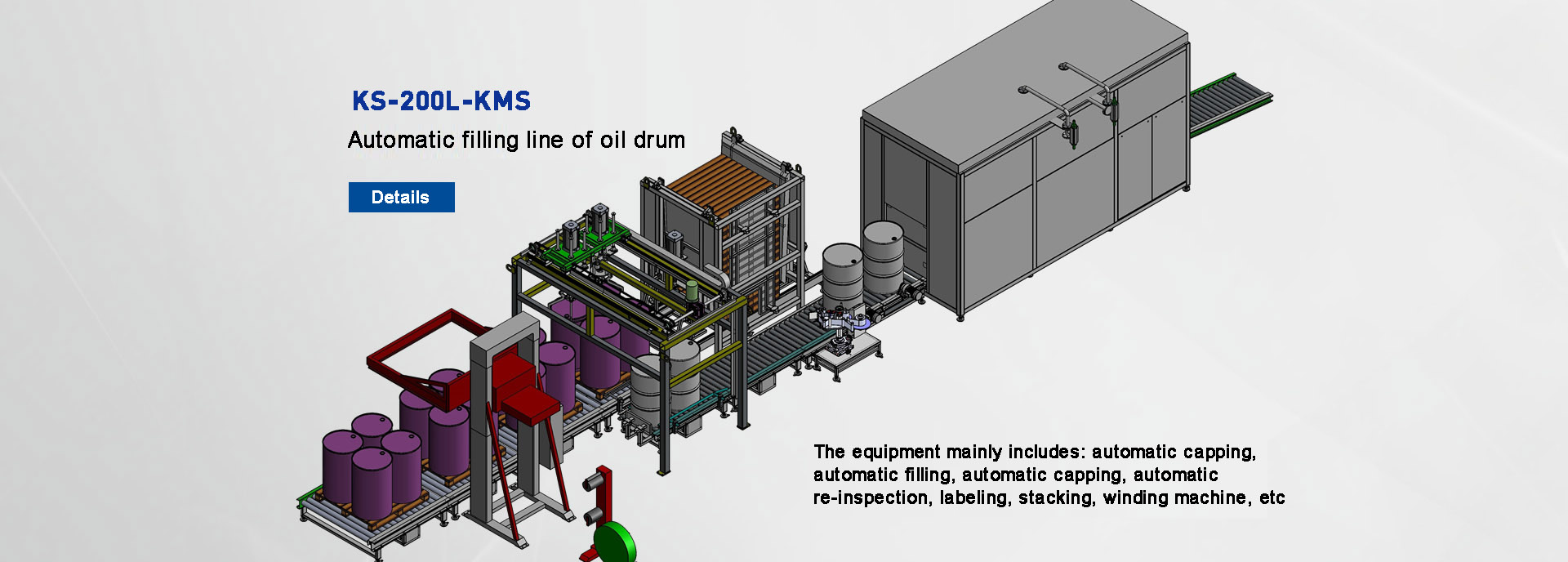

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Company Certificate

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

This is a partial ![]()

service for us

in China.

Over 30 years of experience, every time we produce in

Shanghai, our friends can visit our factory at any time.

Brand components

We will ensure that our company's equipment has safety, stability, high efficiency and intelli-gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternational product brand production and business.

Our service

Complete solution provided

Telephone exchange joint business design plan, you can also visit our company ; we have a good environmental office vehicle,you can visit from time to time.

Duty after death

Our music team has a strong heart, and the customer's suspicions are also the purpose 24 hours of phone cell service and listing to the conversation at any time.

Technology group

We have a wealth of technical personnel and our technical team has been developing technical skills for over ten years.

Successful collaboration

Our factory in Shanghai. China provides free training for our technical staff.Better guarantee good product safety , our company provides safety, convenience, high efficlency packaging servic.

packge and delivery

Multiple Transportation way :Express(Fedex/DHL/TNT/EMS/UPS etc),air and shipping for your choose

FAQs

Our in-house designers and engineers have produced countless great designs for customers from different industries

CONTACT US

Skype: fayfaywang1027

QQ: 429682794

Whatsapp: 008618016442021

E-mail: glzoncn@163.com

https://glzon.en.alibaba.com/

cel: +0086 18016442021