Auto Auger Valve Filling Machine for Powder Flour Coffee Powder Additives Packaging

Automatic Auger Valve Filling Machine for Powder, Flour, Coffee Powder, and Additives Packaging

Overview:

The Automatic Auger Valve Filling Machine is a precision-engineered solution designed to streamline the packaging process for a variety of powdered products including flour, coffee powder, additives, and more. This machine combines advanced technology with user-friendly operation to ensure accurate filling, minimal product waste, and high efficiency in production lines.

Key Features:

Auger Filling Technology:

Utilizes a precision-engineered auger screw mechanism for consistent and accurate filling of powders.

Adjustable auger speed and pitch to accommodate different product densities and flow characteristics.

Versatility:

Capable of handling a wide range of powdered products including but not limited to flour, sugar, salt, coffee powder, spices, and various food additives.

Easily switch between different products with minimal changeover time, enhancing production flexibility.

High Accuracy:

Advanced weighing systems and real-time monitoring ensure precise fill weights, reducing overfilling or underfilling.

Target fill weight can be easily set and adjusted on the intuitive touchscreen interface.

Efficiency:

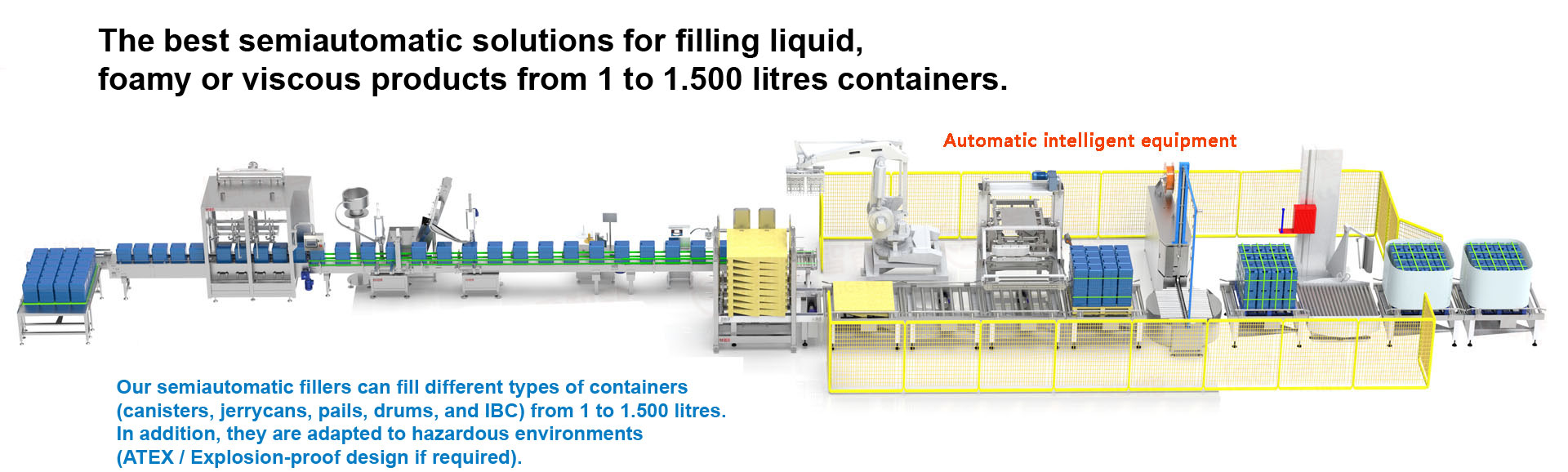

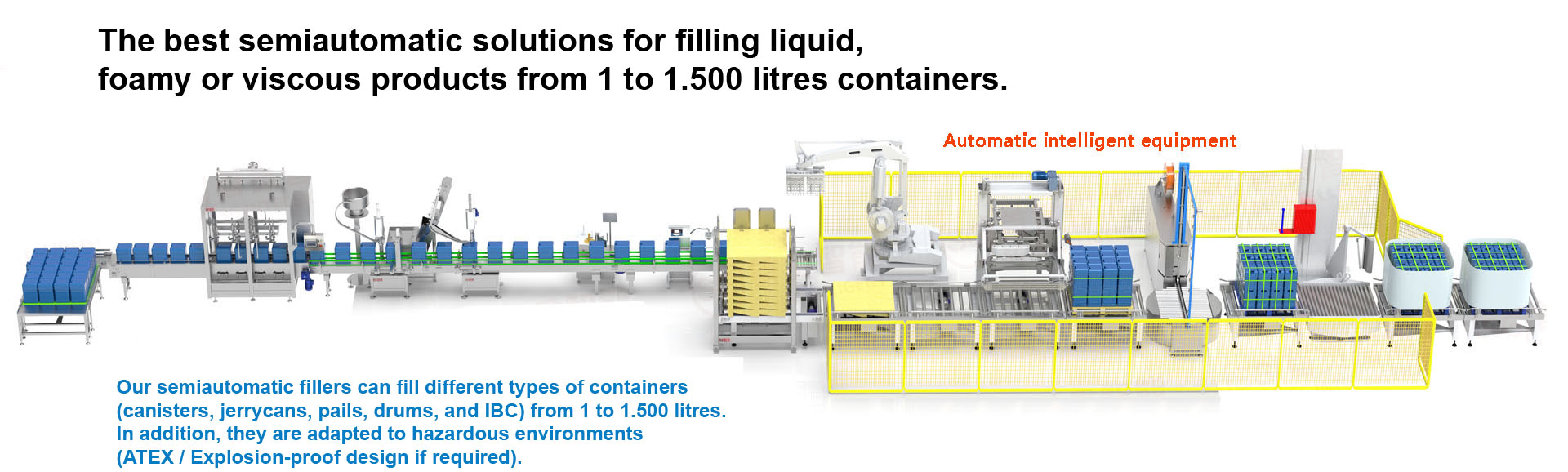

High-speed operation with quick changeover capabilities to maximize productivity.

Automated processes minimize manual intervention, reducing labor costs and increasing throughput.

Hygienic Design:

Constructed from food-grade stainless steel and other materials compliant with food safety standards.

Easy-to-clean design with accessible components and minimal dead spaces to prevent cross-contamination.

User-Friendly Controls:

Intuitive touchscreen interface allows operators to set parameters, monitor performance, and troubleshoot issues with ease.

Programmable logic controller (PLC) for precise control over all functions, including filling, sealing, and batch tracking.

Sealing Options:

Compatible with various sealing methods such as heat sealing, cold sealing, and vacuum sealing to suit different bag types and materials.

Ensures secure, airtight seals to maintain product freshness and extend shelf life.

Safety Features:

Equipped with emergency stop buttons, safety interlocks, and protective covers to ensure operator safety.

Compliant with industry safety standards for reliable and secure operation.

Customization:

Available in various configurations to meet specific needs, including custom hopper sizes, auger designs, and additional feeding systems.

Optional features like dust collection systems, vibration control, and integration with upstream and downstream equipment.

Data Integration:

Integrated data management system for batch tracking, quality control, and compliance reporting.

Capable of connecting to enterprise resource planning (ERP) systems for seamless data flow and inventory management.

Benefits:

Regulatory Compliance: Ensures adherence to strict food and industry regulations, providing peace of mind for quality-conscious producers.

Cost Efficiency: Accurate filling reduces material wastage, lowering production costs and improving profitability.

Product Quality: Consistent and precise filling guarantees uniform product quality, enhancing customer satisfaction and brand reputation.

Ease of Use: User-friendly interface and automated operations simplify the production process, reducing the need for extensive training.

Flexibility: Versatile enough to handle multiple product lines and packaging formats, offering a single machine solution for diverse needs.

Scalability: Suitable for both small-scale and large-scale production, allowing businesses to grow without significant capital investment in new equipment.

Applications:

Ideal for use in:

Food Industry: Packaging of flour, sugar, salt, powdered milk, infant formula, protein powders, and more.

Beverage Industry: Filling and sealing of coffee powder, espresso powder, and other beverage additives.

Pharmaceutical Industry: Handling of medicinal powders, vitamins, probiotics, and other health supplements.

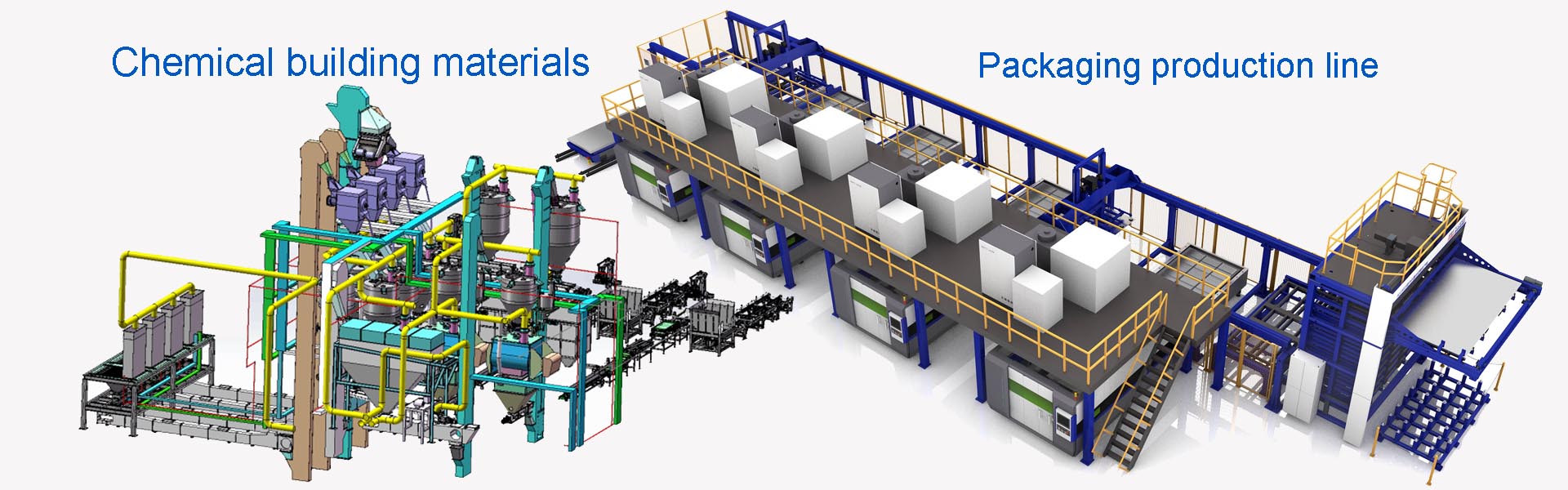

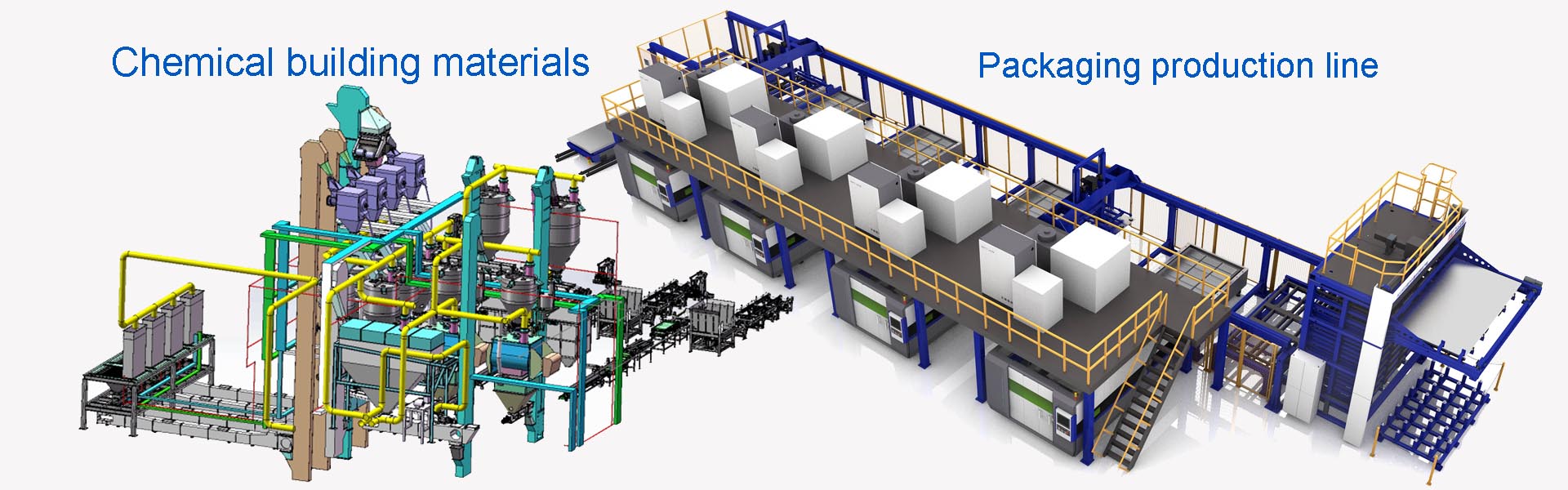

Chemical Industry: Packaging of industrial powders, additives, and other chemical substances.

Invest in the Automatic Auger Valve Filling Machine to enhance your production capabilities, ensure regulatory compliance, and deliver superior quality products to your customers.

Immediate Order:

Website: http://www.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com